- Continuous Screw Pyrolysis Plant

- Continuous Twin-Screw Pyrolysis Plant

- Continuous Rotary Kiln Pyrolysis Plant

- Semi-Continuous Rotary Kiln Pyrolysis Plant

- Batch Rotary Kiln Pyrolysis Plant

- Recovered Carbon Black Refining Plant

- Pyrolysis Oil Refining Plant

- MSW to Energy Plant

- Industrial Solid Waste to Energy Plant

- Waste Gas to Energy Plant

01

Continuous Twin-Screw Pyrolysis Plant

Animation Video

Features

Fully Automated Operation

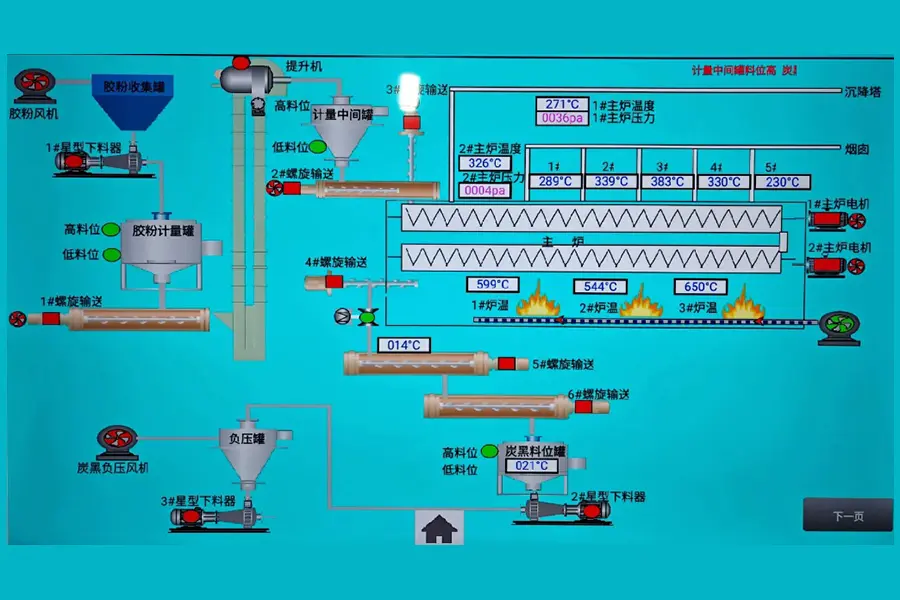

From the initial feeding stage to heating,temperature control, cracking, cooling, oil storage, carbon black collection, combustible gas collection for further utilization, and exhaust gas treatment,each process is seamlessly controlled through advanced PLC automation. Real-time monitoring of temperature, pressure, flow rate, and other operationa parameters ensures optimal performance.

Operators can conveniently manage the equipment's operations from a central control room.

Safety Assurance

By implementing fullautomation, we eliminate the potential risks associated with human error. Our equipment operates with outstanding precision and eliabiity, ensuring a safe and secure environment for operators and the surrounding areas.

Optimal Thermal Utilization

Our equipment employs a cutting-edge hot air heating system that ensures precise temperature control throughout the pyrolysis process. The reactor's internal uniform temperature distribution reduces temperature differentials. Additionally,the reactor is designed with full coverage, eliminating heatloss from exposed areas.

Consequently, our equipment achieves a significantly higher thermal utilization rate than other products in the market, leading to substantial energy savings and lower emissions.

Extended Lifespan

Through the implementation of our hot air heating design, which surpasses traditional direct combustion heating methods, we have tripled thelifespan of the reactor. This ensures long-term operational efficiency, minimizing downtime and maximizing returns on investment.

Remarkable Production Efficiency

While conventional batch pyrolysis equipment typically handles up to 10 to 15 tons per unit,our continuous equipment significantly boosts production capabilities, allowing for a daily processing capacity of up to 30 tons, with a maximum capacity of 50 tons.Moreover,thanks to advanced technological designs,our equipment features a more compact footprint,allowing for enhanced production efficiency compared to similar products available on the market.

Superior Production Quality

Huayuan's continuous twin-screw pyrolysis plant design incorporates an upper and lower stratification,strategically placing the outlets for oil products and carbon black at opposite ends of the reactor. This configuration ensures zero interference between oil product and carbon black production, thereby maximizing the quality of the end products.

Minimal Maintenance

Distinguishing itself from conventional packing seals, our equipment employs advancedmechanical seals equipped with dedicated lubrication and cooling systems. This innovative approach ensures a maintenance-free lifespan,signiicantly reducing maintenance demands and associated costs.

Zero Pollution Exhaust Gas Emission

Huayuan's latest continuous twin-screw pyrolysis reactor achieves zero pollution in both exhaust gas emissions and discharging process.This exceptional achievement sets it apart from traditional alternatives.

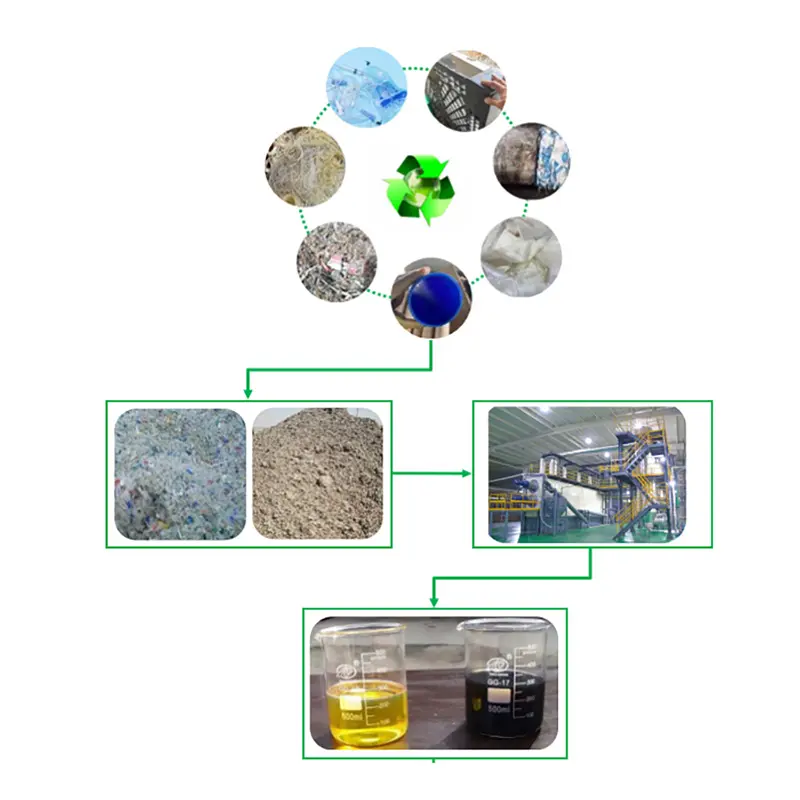

The process of continuous twin-screw pyrolysis plant for waste plastic

→ The Plastic scrap is shredded into flake or powder.

→ Heat the reactor with external energy, such as diesel oil(about 600-900kg) or natural gas.

→ The powder is continuously to be fed into the drum reactor.

→ The powder is converted into gas and carbon black in the reactor.

→ The gas goes into the condensers. Some gas is cooled down to liquid oil. Some is No Condensable Gas, we call it NCG. The NCG will be used as fuel to heat the reactor, so no need external energy any more.

→ The oil goes into oil tank and carbon black will be automatically transferred to the carbon black refining system to make pellets.

→ The flue gas produced by the pyrolysis line will be cleaned to meet the environmental standard then discharged.

| 1 | Feeding system | 8 | Cooling Tower |

| 2 | Pyrolysis Reactor | 9 | Extra Gas burning Room |

| 3 | Reactor Basement and Bruning Room | 10 | Sync Gas Purifying System |

| 4 | Gas Separator | 11 | Water Seal |

| 5 | Condensers | 12 | Smoke Clean System |

| 6 | Oil Tanks | 13 | Chimney |

| 7 | Carbon Black Discharging System | 14 | Control Cabinet |

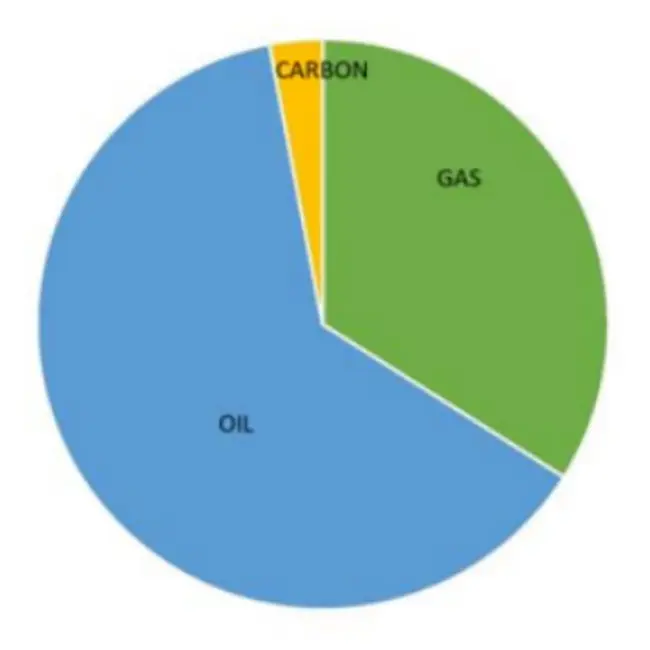

During plastic pyrolysis three main products are newly created:

. Plastic pyrolysis oil" 63% to 90%

. Non-condensable gas: 3% to 34 wt.%

. Carbon black: 3% to 8 wt.%

Approx oil yield of different raw materials

| PE | 0.9 |

| PP | 0.9 |

| PS | 0.9 |

| ABS | 0.4 |

| Leftovers of paper | Wet 15%-20%, dry 60% |

| House garbage | 35%-50% |

| Plastic cable | 0.8 |

| Plastic bag | 0.5 |

| Submarine cable | 0.75 |

| Rubber cable | 0.35 |

| Sole | 0.3 |

| Big tires | 45%-50% |

| Small tires | 35%-40% |

| PVC | Not suitable |

| PET | Not suitable |

TECHNICAL DATE

| Unit Capacity | 30-50 Tons Per Day |

| Production Mode | Continuous Type |

| Overall Dimension | 40mx8mx9m(LxWxH) |

| Total Weight | 100~120 Tons |

| Internal Volume of Reactor | 20.41~40 CBM |

| Condensing System | Integrated Condenser |

| Emission Control System | Stainless Steel Scrubbers plus Internal Fiters |

| Heating System | Hot Air Heating System |

| Feeding System | Bucket Elevator and Screw Conveyor |

| Carbon Black Collection System | Screw Conveyor and Pneumatic Conveyor |

| Shipping | Containerized |

| Construction | Modular Design |

| Custom Specifications | According to your location requirements |

APPLICATION

For our continuous twin-screw pyrolysis plant, the applicable raw materials can be any kinds of waste tires, such as bicycle tires, motorcycle tires, car tires, truck tires, OTR tires,plastic,etc.

Application of fully continuous twin-screw pyrolysis plant

Excpet the steel wire extracted out from waste tires in the first stage pretreatment process, the final products from waste tire pyrolysis process will be fuel oil and carbon black.

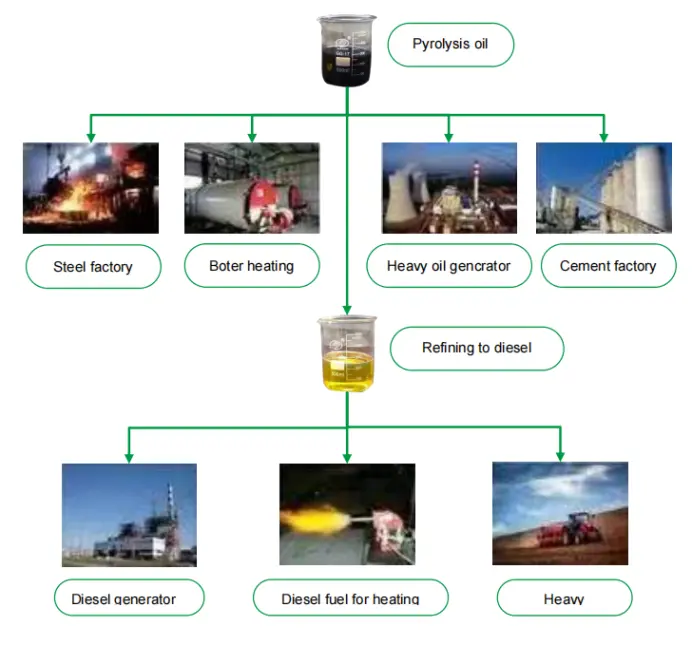

When the whole process is over, we can get end-products that have a wide range of applications. For example, the pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc. or used for generators to get electricity. The carbon black can be used for making construction bricks with clay, or used as fuel. The steel wire can be sold directly or recycled to produce new steel products.

CUSTOMER CASE VIDEO

Contact Us