- Continuous Screw Pyrolysis Plant

- Continuous Twin-Screw Pyrolysis Plant

- Continuous Rotary Kiln Pyrolysis Plant

- Semi-Continuous Rotary Kiln Pyrolysis Plant

- Batch Rotary Kiln Pyrolysis Plant

- Recovered Carbon Black Refining Plant

- Pyrolysis Oil Refining Plant

- MSW to Energy Plant

- Industrial Solid Waste to Energy Plant

- Waste Gas to Energy Plant

01

Continuous Pyrolysis Plant(Rubber Powder As Feedstock)

Animation Video

Features

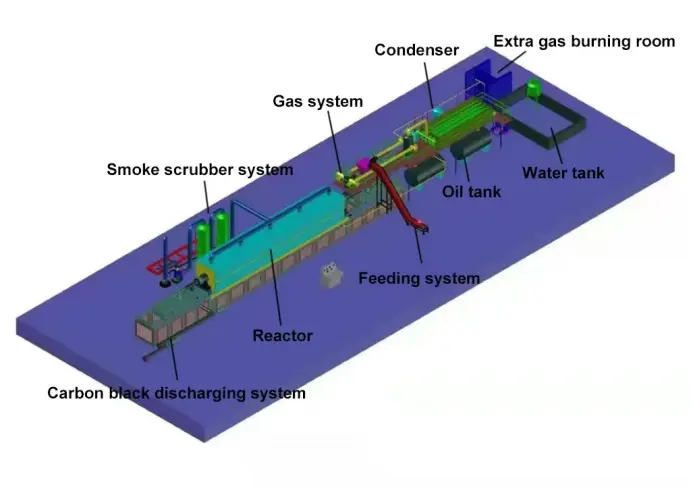

Product introduction of industrial Continuous pyrolysis plant(5-10cm tire blocks as feedstock)

Continuous pyrolysis plant(5-10cm tire blocks as feedstock) includes waste tyre pretreatment system(shredder and crusher), continuous pyrolysis system with continuous feeding and discharge system controled by PLC system, RCB refining system. The main part is the continuous pyrolysis system. Continuous waste tyre pyrolysis plant is for processing waste tyres into fuel oil and carbon black for recycle use. Due to continuous feeding and discharge system, the continuous waste tyre pyrolysis plant can keep working without stop, thus to save energy and time. Also PLC control system makes much less labour cost.

Continuous pyrolysis plant(5-10cm tire blocks as feedstock)

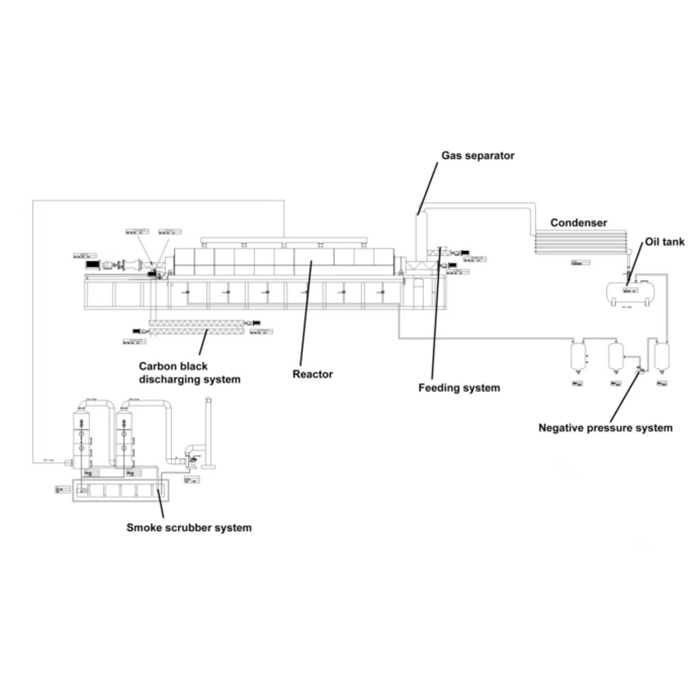

Working process of industrial continuous waste tyre pyrolysis plant

To keep continuous feeding and discharge system, it requires the waste tyres should be in small size. So before continuous pyrolysis process, the waste tires should be shredded into small pieces. And to avoid the steel wire mix with carbon black after pyrolysis process which is difficult to separate, it’s better to remove the steel wire from waste tires at first. As for detailed process, please check as below:

| 1 | Feeding system | 8 | Cooling Tower |

| 2 | Pyrolysis Reactor | 9 | Extra Gas burning Room |

| 3 | Reactor Basement and Bruning Room | 10 | Sync Gas Purifying System |

| 4 | Gas Separator | 11 | Water Seal |

| 5 | Condensers | 12 | Smoke Clean System |

| 6 | Oil Tanks | 13 | Chimney |

| 7 | Carbon Black Discharging System | 14 | Control Cabinet |

3D picture of Continuous pyrolysis plant(5-10cm tire blocks as feedstock)

1. Shred waste tire to tire block (<10-15cm)

Separate tires, put passenger tires and truck tires and OTR tires in different group.

In order to ensure long life span of shredder, different tires use different shredder.We have 3 different shredders for OTR tires, Truck tires and passenger tires.

The thick tread wire will be removed during this process.

2. Crush tire block to tire powder system(10mesh to 2mm)

Crush the tire block to tire powder. The steel wire will be removed also during this process.

3. Continuous pyrolysis

The tire powder go into the continuous waste tyre pyrolysis plant, will firstly go through a mutiple pyrolysis reactor system to be pyrolyzed into oil gas. And oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon black) will be pushed to the carbon black dischrge system for discharge.

4. Carbon black refining

The carbon black from pyrolysis machine is just carbon char. It can not be used as feedstock for new tires factory. It should be refined. First mill it to find powder(300-1000mesh), then make rcb pellets, and then dry it.

Main features of continuous pyrolysis plant

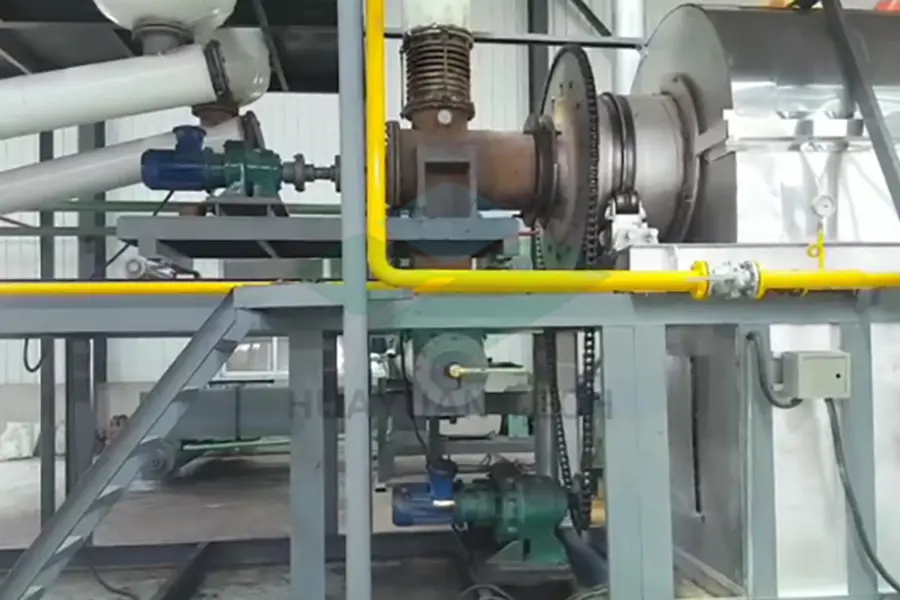

1. Screw pyrolysis reactor

Compared with continuous drum pyrolysis reactor, the continuous screw pyrolysis reactor can run much longer time with its coking clean system.

2. Advanced seal part

For drum pyrolysis reactor, you have to change the sealing material every week, thus cannot achieve the real sense of continuous process. Our screw running model continuous waste tyre pyrolysis reactor adopts advanced liquid film seal part, which no need to worry about the leak of oil gas.

3. Fully automatic with low labour cost

Our conitnuous waste tyre pyrolysis plant is controled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating.

4. Fully pyrolysis for high oil output

Our continuous waste tyre pyrolysis plant adopts screw running model reactor design which can make fully pyrolysis of waste tires, thus to get high oil output.

5. Big capacity

Also due to continuous feeding and discharge system, and unique mutiple reactor design, our fully automatic continuous waste tyre pyrolysis plant can process at least 10 tons waste tires per day, up to 100T/D.

6. Continuous working save time and energy

7. Long working life

During the continuous pyrolysis process, reactor heating is by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors. And since the hard steel wire already removed from waste tires before pyrolysis processs, thus no damage for the reactor.

TECHNICAL DATE

| No. | Item | Specifications | ||

| 1 | Model | HY-C-20 | HY-C-30 | HY-C-50 |

| 2 | Capacity | 20T/D | 30T/D | 50T/D |

| 3 | Power | 70Kw | 85Kw | 100Kw |

| 4 | Working type | Continuous | ||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||

| 6 | Rotating | Internal rotating | ||

| 7 | Cooling system | Recycled waster cooling | ||

| 8 | Reactor material | Q345R boiler plate and stainless steel | ||

| 9 | Heating method | Indireact hot air heating | ||

| 10 | Heating fuel | Fuel oil/gas | ||

| 11 | Feedstock | Waste tire/plastic/rubber | ||

| 12 | Output | Fuel oil, carbon black | ||

APPLICATION

Application of fully continuous waste tyre pyrolysis plant

For our continuous waste tyre pyrolysis plant, the applicable raw materials can be any kinds of waste tires, such as bicycle tires, motorcycle tires, car tires, truck tires, OTR tires, etc.

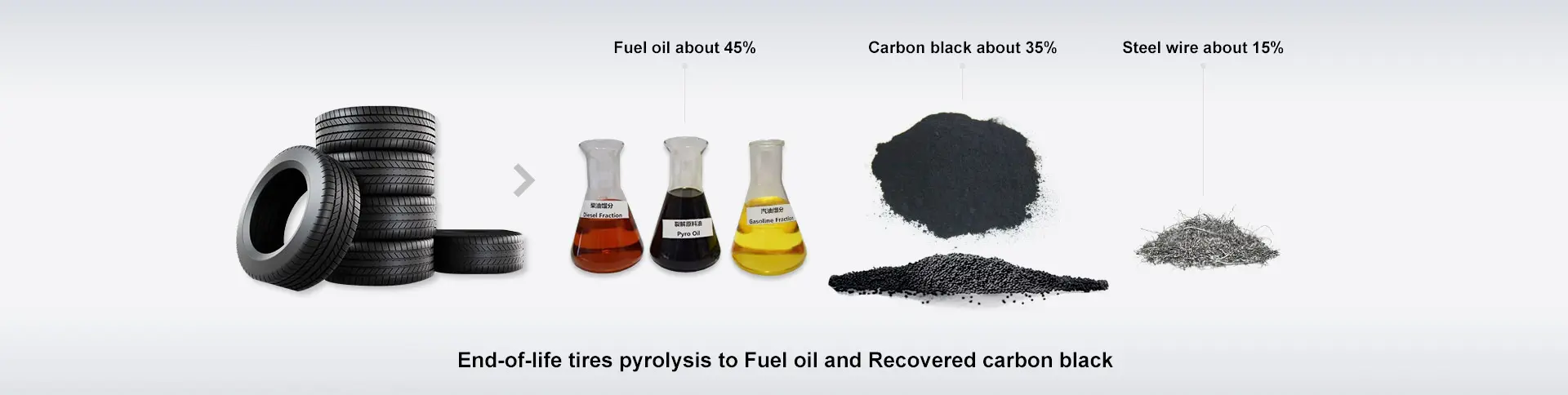

Excpet the steel wire extracted out from waste tires in the first stage pretreatment process, the final products from waste tire pyrolysis process will be fuel oil and carbon black.

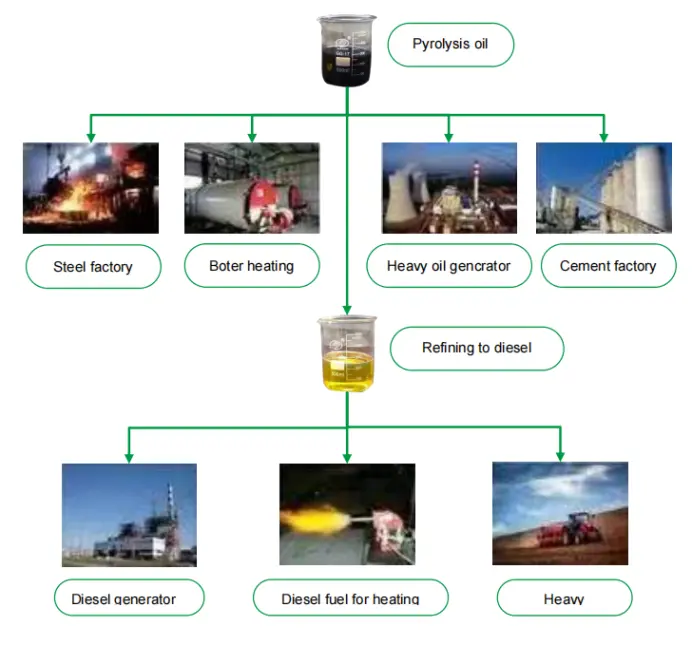

When the whole process is over, we can get end-products that have a wide range of applications. For example, the pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc. or used for generators to get electricity. The carbon black can be used for making construction bricks with clay, or used as fuel. The steel wire can be sold directly or recycled to produce new steel products.

CUSTOMER CASE VIDEO

Contact Us