What kinds of equipments you could provide?

Pyrolysis plant and incineration plant.

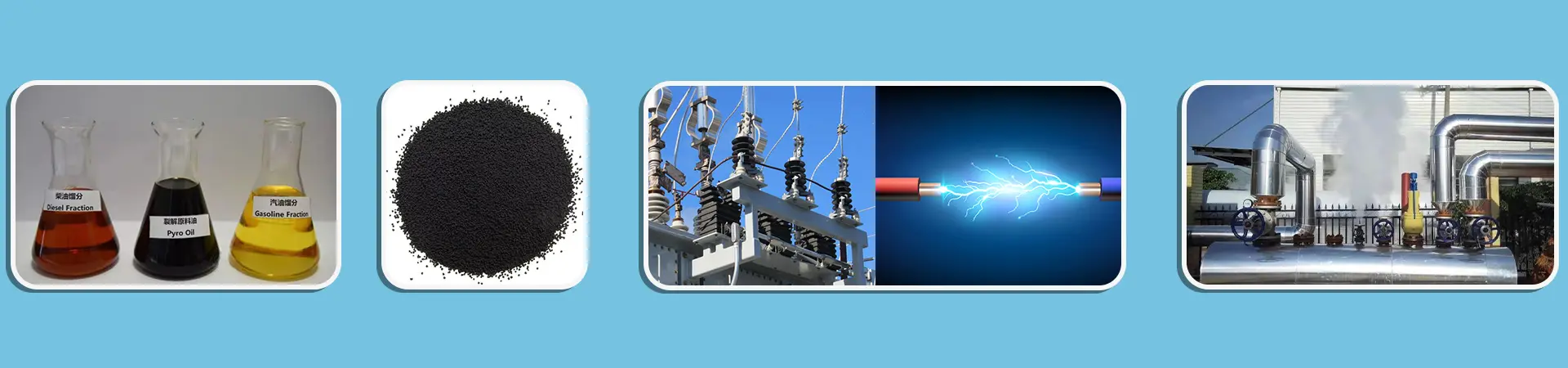

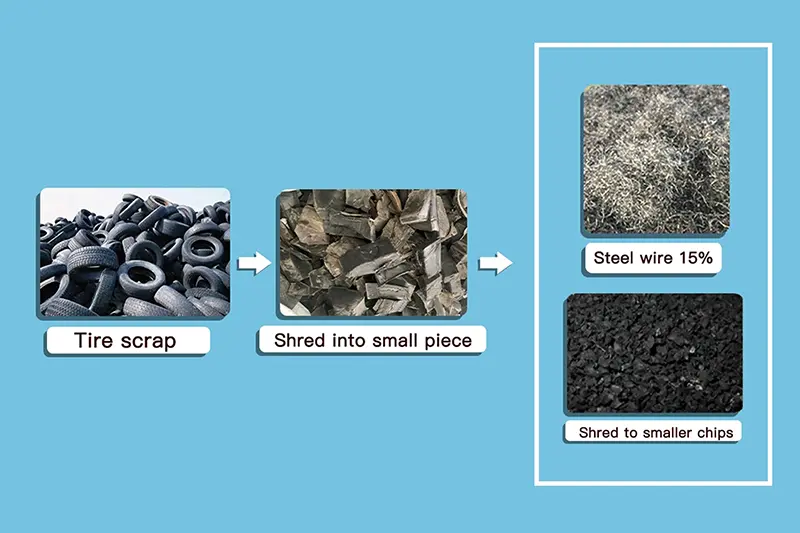

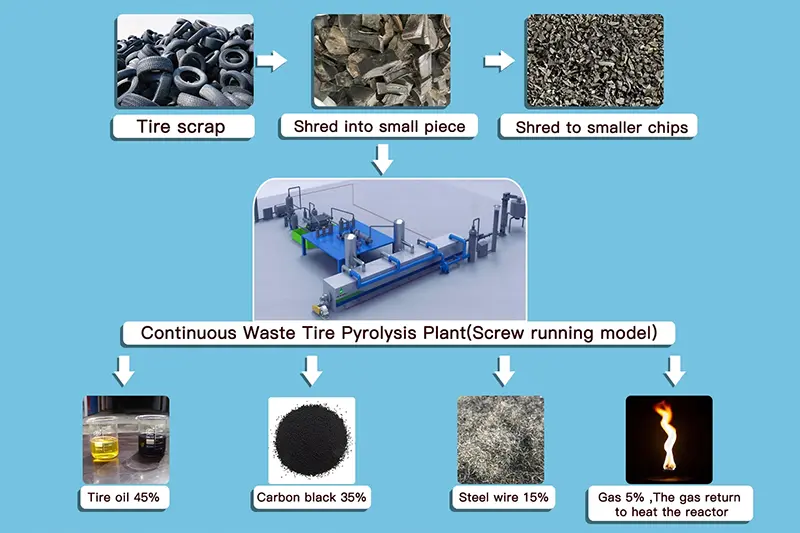

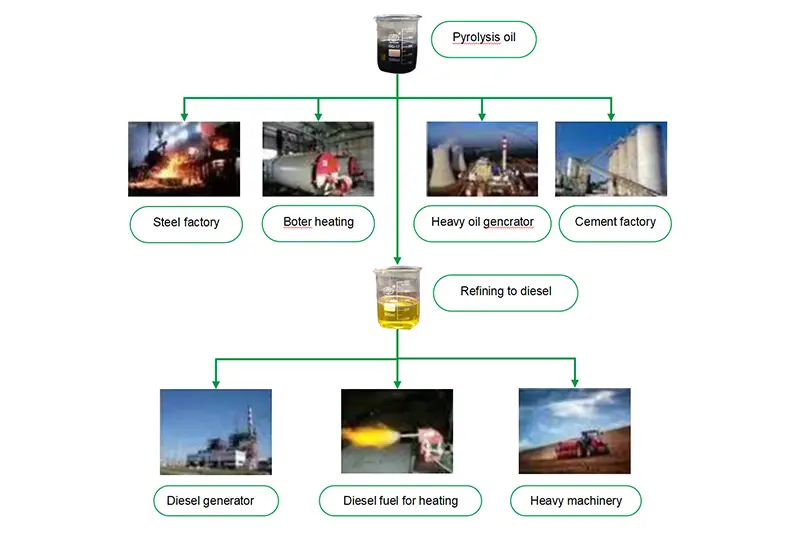

Pyrolysis plant can convert waste tire or plastic to fuel oil and recovered carbon black.

Incineration plant is Waste To Energy plant, it can convert MSW or industrial waste to electricity or steam.

The detailed as following:

1. Continuous waste tire pyrolysis plant(Screw running model)

2. Continuous Waste Plastic Pyrolysis Plant(Screw running model)

3. Continuous Waste Tire Pyrolysis Plant(Drum running model)

4. Semi-continuous Model Pyrolysis Plant(Drum running model)

5. Batch Model Pyrolysis Plant(Drum running model)

6. Recovered Carbon Black Refining Plant(Drum running model)

7. Pyrolysis Oil Refining Plant

8. MSW To Energy Plant

9. Industrial Three Wastes To Energy Plant

10. Waste Heat To Energy Plant

What is the difference between screw running model pyrolysis machine and drum running model pyrolysis machine?

Its reactor is different. There is a screw in the reactor of screw running model pyrolysis machine. The screw move, the drum not move.

There is no independent screw in the reactor of drum running model pyrolysis machine. The screw is welded in the inside of drum. The drum and screw move together.

Can you tell me the history of your pyrolysis machine?

We have experienced 4 generations pyrolysis machines. The first generation is batch model pyrolysis machine. The second generation is semi-continuous model pyrolysis machine. The 3rd generation is drum running model continuous pyrolysis machine. The 4th generation is screw running model continuous pyrolysis machine.

What is advantage of your screw running model pyrolysis machine?

Self-clean coking technology ensure long time running. It can run 100 days continuously.

Advanced mechanical seal, there is no any oil leak from the seal area. Advanced DCS control system. From feeding to end product, can be controlled in the control room. It can meet the need of USA and European markets.