- Continuous Screw Pyrolysis Plant

- Continuous Twin-Screw Pyrolysis Plant

- Continuous Rotary Kiln Pyrolysis Plant

- Semi-Continuous Rotary Kiln Pyrolysis Plant

- Batch Rotary Kiln Pyrolysis Plant

- Recovered Carbon Black Refining Plant

- Pyrolysis Oil Refining Plant

- MSW to Energy Plant

- Industrial Solid Waste to Energy Plant

- Waste Gas to Energy Plant

01

Industrial Solid Waste to Energy Plant

Application Scope

Production of toxic waste water, waste residue, waste gas produced in the petrochemicalindustry or can not be handled by general biochemical methods Waste water, waste residue,exhaust gas, only the use of high temperature incineration method. Experience to introducethe above waste at 1000 ℃ under the conditions of stay Between> 1.5S can be decomposedinto harmless emissions, can be considered denitrification, desulfurization, dust.

Technical Advantages And Characteristics

1. The use of high-efficiency co-combustion fumace technology, high pollution, difficult to degrade andtoxic waste water, waste gas, waste and other fuels at the same time into High-temperature incineration,.set burning, efficient combustion, pyrolysis as a whole, completely overcome the combustion is notcomplete, environmental pollution is not up to standard technology problem.

2. The incinerator and the heat recovery furnace into a furnace, to achieve the integration, integration,compact structure,reduce land area, Save investment.

3. incineration fumace with a special vertical, closed structure, to achieve continuous gray and longsystem operation, to improve the burning rate.

4. Load regulation characteristics, and can be stable in the range of 30% ~ 100% rated load, to achievethe effect of economic operation;

5. incinerator automatic control, combustion stability, high security, easy operation and maintenance.

Industrial System

Industrial "three wastes" high-temperature harmless treatment incineration boiler and system

Using low calorific value industrial waste liquid (water), waste gas and waste residue as fuel, supplemented by oil (gas) ignition system, using high-efficiency co-firing incineration technology, the industrial three wastes are used as resources and harmlessly used, turning waste into treasure. Incineration + waste heat recovery integrated boiler, the furnace type includes different furnace types such as steam/hot water/conducting oil/hot air, etc., which can be customized according to the user's individual needs to fully meet market demand!

Fuel Technical Index

Waste liquid (water): sewage containing various organic, inorganic, and toxic substances, waste liquid in the chemical industry, wastewater in the sewage treatment industry, wastewater in the textile printing and dyeing industry...

Exhaust gas: soot, odor, irritating gas and other harmful gases, biological gas, waste gas in the steel industry, waste gas in the chemical industry...

Waste slag: fly ash, calcium carbide slag, coal slime, paper industry waste slag, leather industry dry sludge...

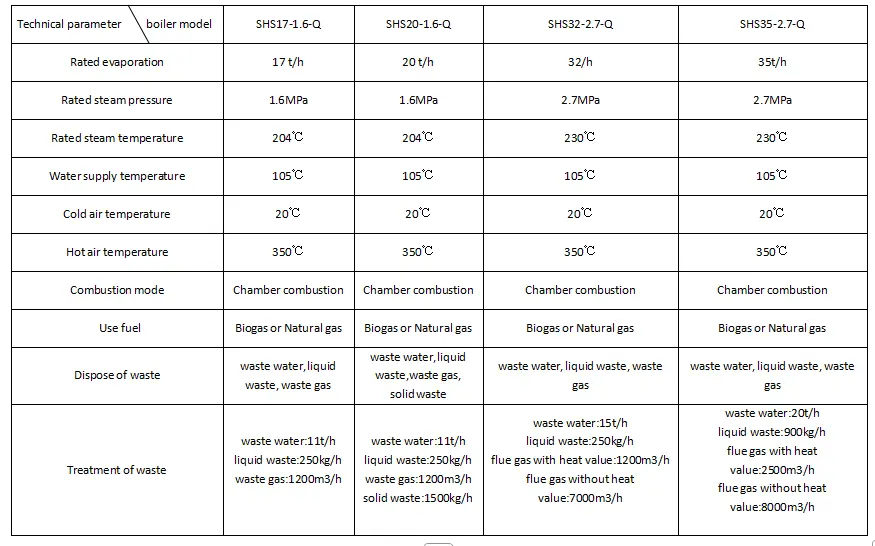

Boiler technical characteristics

High-efficiency mixed combustion technology can be used to incinerate high-pollution, difficult-to-degrade and toxic industrial three wastes at a high temperature at the same time, integrating incineration, high-efficiency combustion, pyrolysis, and waste heat recovery;

The incinerator and waste heat recovery are made into an integrated furnace, which realizes integration and integration, has a compact structure, reduces floor space and saves investment;

The incinerator adopts a special vertical closed structure to achieve continuous long-term operation;

Load regulation number, which can run stably in the range of 30%~110% of rated load;

Engineering Applications

The system can be widely used in waste liquid and waste gas treatment in the petrochemical industry, waste liquid and waste gas treatment in the printing and dyeing textile industry, waste residue and waste water treatment in the paper industry, waste residue and waste liquid in the biopharmaceutical industry, and users covering the petrochemical industry, building board processing, Different fields such as food textile industry and paper industry.

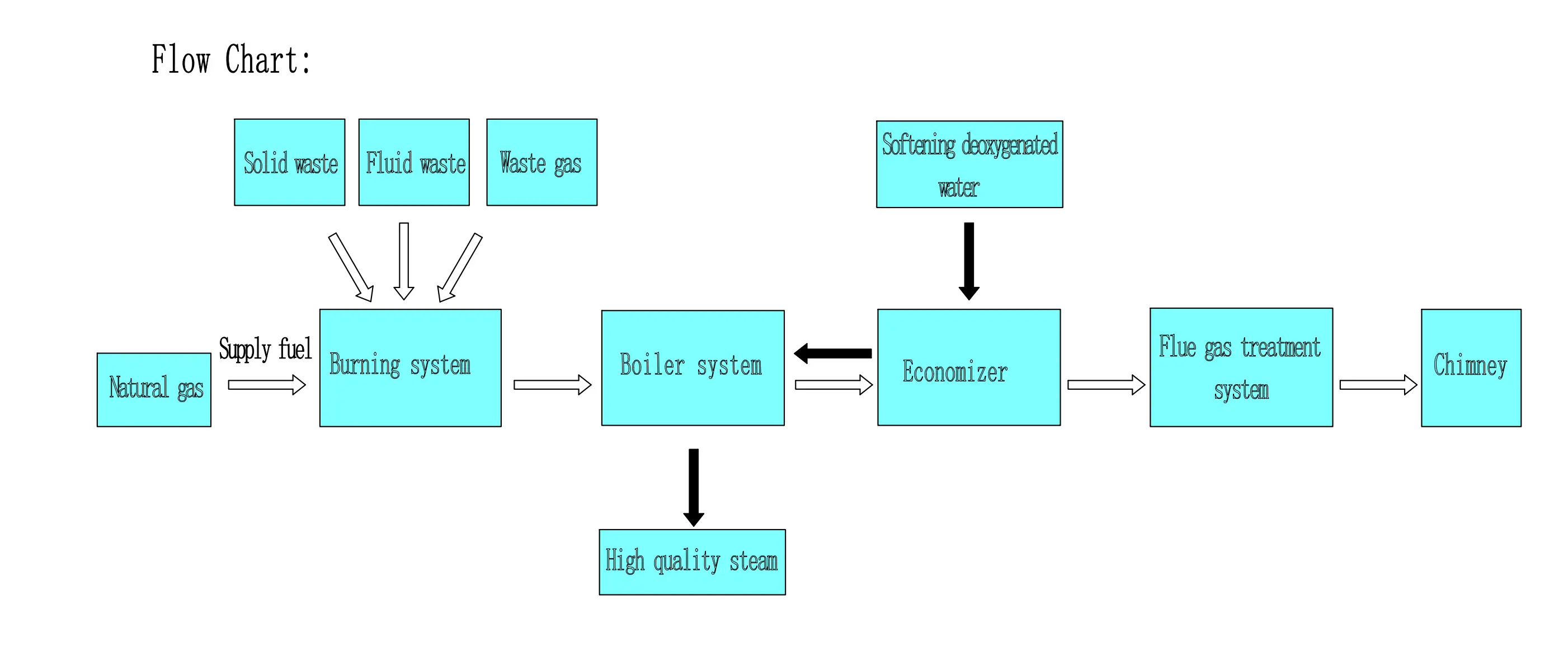

Flow Chart

Fine chemical industry waste oil waste residue incineration boiler

Formaldehyde waste gas incineration boiler

The wastewater high-temperature incineration boiler

Contact Us