A fresh focus on new approaches to recycling tyres is needed

The number of vehicles is growing worldwide and as a result the number of tyres is increasing too. Hundreds of millions of tyres are discarded each year. Their disposal represents a major global problem.

There are serious hazards associated with stockpiling used tyres, such as uncontrollable fires. There is also the problem of illegal dumping, which results in pollutants and promotes growth of pests and insects. And burning tyres leads to the emission of harmful compounds.

Recycling tyres has been the main focus so far, but it is not enough to get rid of the massive number of waste tyres generated each year. There are alternatives, such as retreading, but they have major limitations. More eco-friendly recycling alternatives are now being explored.

But finding efficient recycling technologies for tyres is difficult because of their composition. Tyres are made of rubber, carbon black, steel and some additives. These are difficult to break down and separate, which makes reprocessing hugely challenging. Hence the need to develop new technologies.

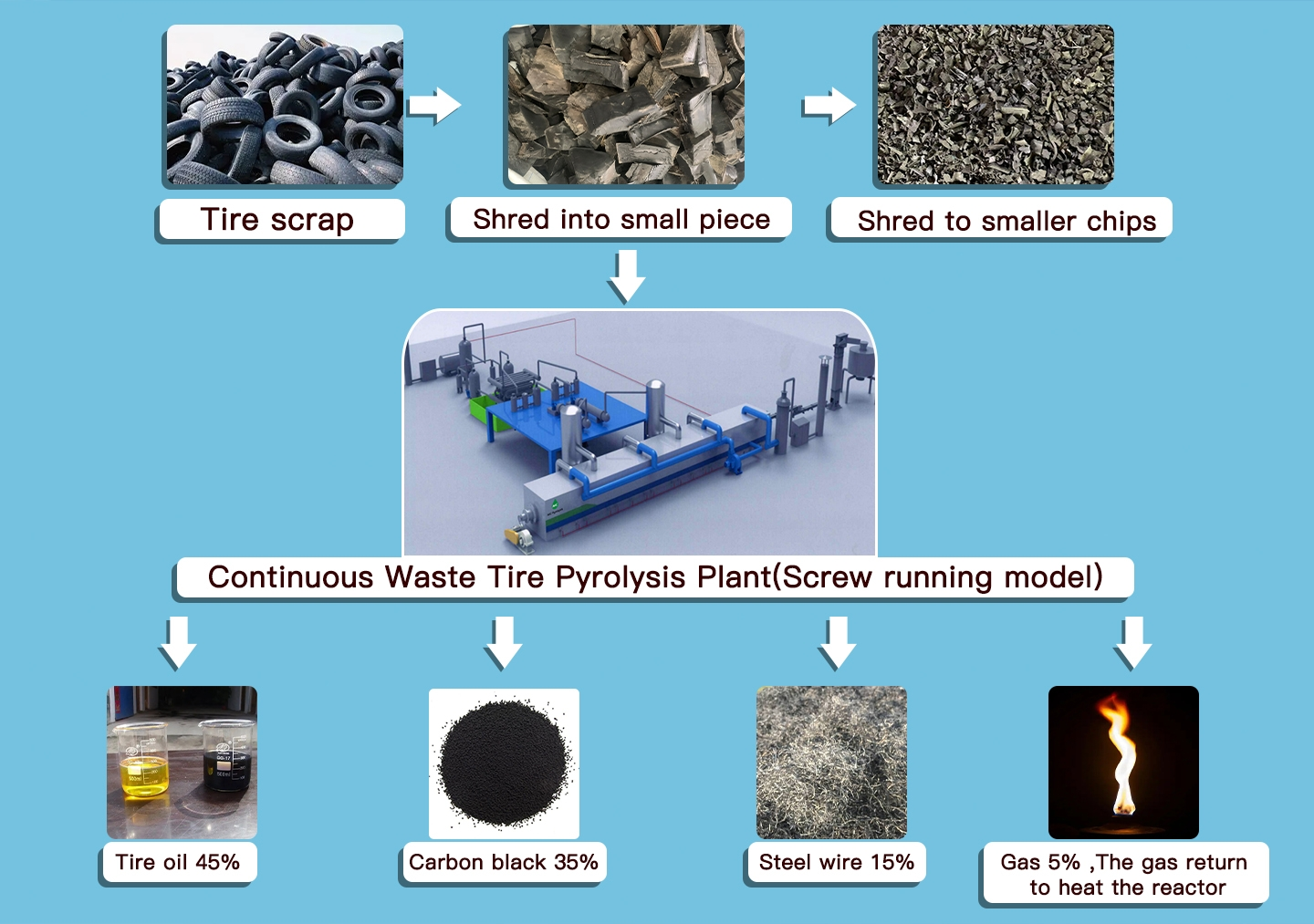

One avenue being explored is valorisation – the processing (at industrial scale) of waste products and turning them into useful products or sources of energy. For example, raw materials such as rubber, carbon black or steel can be recovered from used tyres and used in other applications. It is also possible to extract energy in the form of combustible materials with high calorific value.

Recycling only goes so far

MaterialS Recycling goes in several directions. These include civil engineering applications like road constructions, the manufacture of swings and shoe soles, and shoring up embankments.

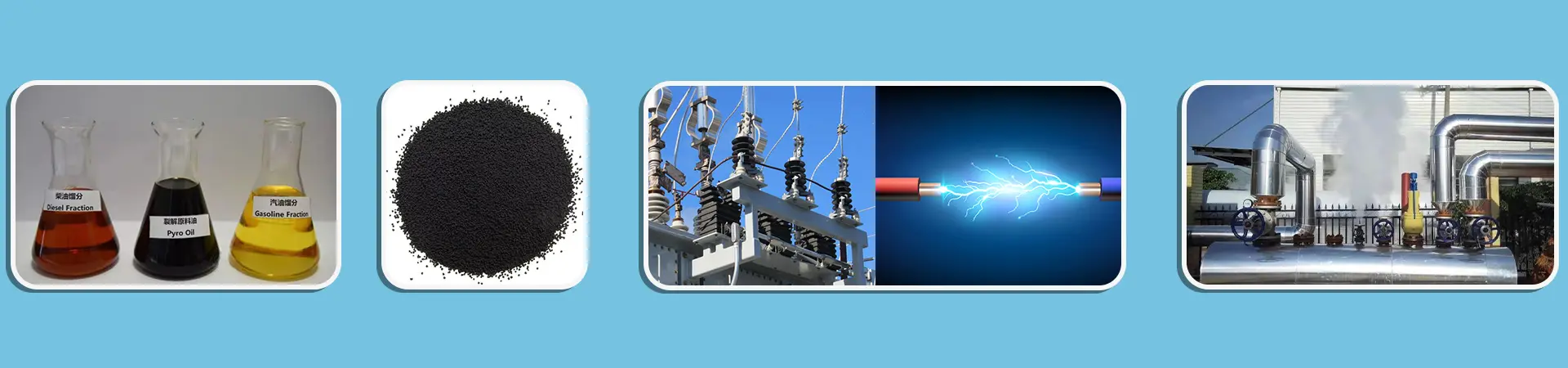

Pyrolysis is proving to be a promising form of Waste Tyre Recycling, with the production of potentially valuable products. It consists of “burning” the material at high temperatures in an atmosphere free of air to obtain a gas, an oil and a solid.

Pyrolysis products can be managed easily and separated for different applications. The gas fraction can be used in boilers to obtain energy. The most abundant fraction, the liquid, can be separated into expensive raw materials like the hydrocarbon limonene. The solid fraction (>80% carbon) may be used as activated carbon or carbon black.

Finding an efficient way of reusing and recycling used tyres will have a positive impact on the environment, as the recycling of a discarded material will avoid the use of new fossil fuel as coal or petroleum. For example, the oil obtained from pyrolysis can replace diesel fuel. This in turn will mean a reduction in greenhouse gas emissions.

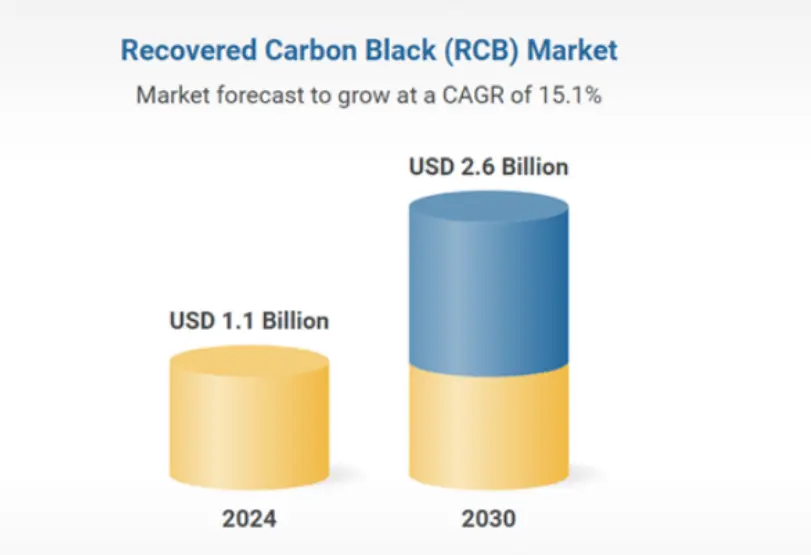

More environmentally friendly processes have to become more economically and environmentally attractive, leading to the reduction of the large stockpiles of tyres and the creation of revenue.