Carbon Black (CB) & Recovered Carbon Black (rCB): A Sustainable Shift in the Rubber Industry

Introduction

Carbon Black (CB), a versatile material widely used in plastics, inks, paints, and rubber products (notably tires), accounts for a significant portion of global industrial fillers. However, recycling CB from end-of-life rubber—especially tires—remains challenging due to the inherent difficulties in rubber reprocessing, often relegating it to a disposable byproduct. Growing environmental concerns have spurred research into recovering CB from discarded rubber, aiming to reduce the industry’s ecological footprint. This article presents findings from an Artis-funded study and collaborative experiments by Michelin and Bridgestone, focusing on the properties of Recovered Carbon Black (rCB) and the urgent need to establish standardized evaluation criteria.

The Rise of rCB: A Sustainable Alternative

As sustainability gains prominence in the rubber industry, rCB has emerged as a viable substitute for fossil-based fillers. Conventional CB is produced through incomplete combustion of vegetable oils or petroleum derivatives (e.g., coal tar), whereas rCB is extracted from recycled rubber—a critical innovation given that tires alone consume 70% of global CB output. This shift could substantially reduce the industry’s carbon emissions.

However, as a novel filler class, rCB’s performance-determining properties require thorough analysis. Research by Norris (Murfitts Industries), López Cerdán (Artis), and ter Haar (Circtec) highlights the impact of aggregate size distribution (ASD), silica content, carbon residues, and organic impurities on rCB consistency. These factors dictate its suitability for industrial applications.

Key Parameters Defining rCB Quality

Aggregate Size Distribution (ASD)

CB exists in colloidal form, composed of primary particles (10–300 nm) that rapidly aggregate into clusters (up to 500 nm) and larger agglomerates (exceeding 100 µm). Unlike uniform commercial CB, rCB’s ASD varies due to the heterogeneity of end-of-life tires. ASD is a critical indicator of rCB’s reinforcement potential. Studies reveal that rCB’s broader ASD reduces quasi-static properties (e.g., elastic modulus variance under deformation) compared to conventional CB with similar colloidal traits. Thus, ASD is proposed as a primary metric for rCB characterization.

Silica and Residual Content

rCB inherits silica, carbon residues, and organic compounds from tire feedstock. Controlled retention of organic residues, for instance, can enhance dispersion and tensile strength. Standardizing these parameters is essential to ensure predictable performance.

Industry Collaboration: Michelin & Bridgestone’s White Paper

In 2022, Michelin and Bridgestone outlined a joint initiative to accelerate rCB adoption, emphasizing:

Standardization: Defining grades/specifications for rCB in tire production.

Supplier Engagement: Aligning rCB quality with industry requirements.

Circularity Goals: With 1 billion tires (30 million tonnes) discarded annually, <1% of CB is currently recycled. rCB could cut CO₂ emissions by 85% versus virgin CB.

Classification Challenges and Future Outlook

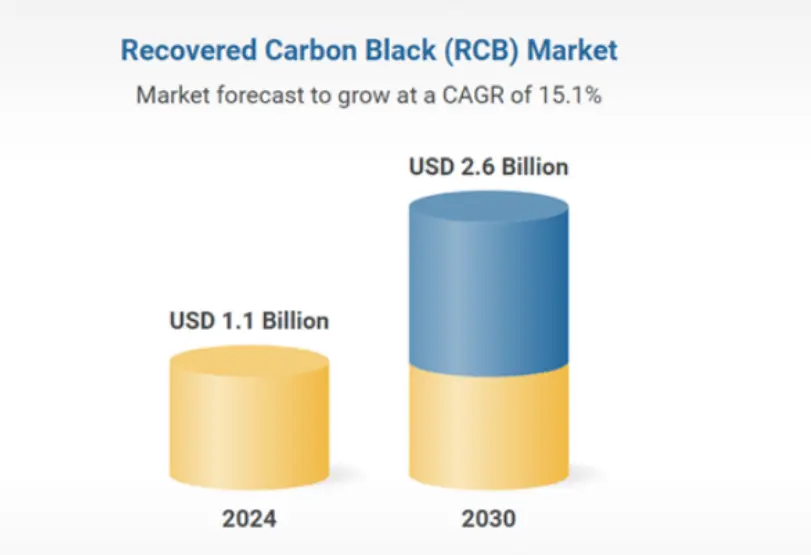

Bridgestone and Michelin project an rCB market of 1 million tonnes/year by 2030, but achieving this demands immediate action. rCB’s composition varies based on tire type (e.g., "soft" N7xx/N6xx grades vs. "hard" N1xx/N3xx tread grades) and pyrolysis conditions. Preliminary ASTM-based classifications (Grades A–D) have been proposed, yet gaps remain in environmental and safety criteria under REACH regulations.

Conclusion

rCB represents a transformative opportunity for tire circularity. While hurdles persist in scalable production and standardization, collaborative research and industry commitment are paving the way for a greener future.