Plastic pyrolysis − chemists explain a technique attempting to tackle plastic waste by bringing the heat

In 1950, global plastic production was about 2 million tons. It’s now about 400 million tons – an increase of nearly 20,000%.

As a material, it has seemingly limitless potential. Plastic is inexpensive to produce while being lightweight and sturdy. Its applications range from food and beverage packing to clothing and health care.

When a plastic item ends its useful life, it can take a very long time to decompose, up to 500 years in some cases. Even then, the plastic pieces don’t disappear entirely – instead, they break down into smaller and smaller pieces, eventually becoming microplastics that end up in the soil where we grow food, the water we drink and the air we breathe.

Research has linked these microplastics to health issues such as diabetes, heart disease and low male fertility.

For years, local governments and manufacturers have relied on recycling as the answer to keep plastic waste from accumulating. However, despite their efforts to sort and separate recyclables, most plastics still end up in landfills – or worse, in green spaces and waterways.

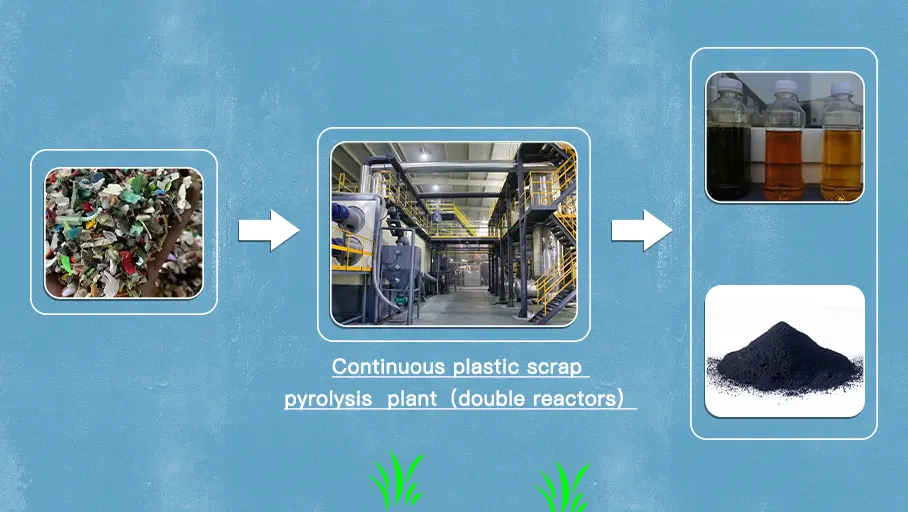

Because plastic is so commonly used, finding new ways to manage and Recycle Plastic waste is becoming ever more important. Plastic waste pyrolysis is one technology that could help address this issue.

This is a relatively new technique, so researchers still have only a limited knowledge of the pyrolysis process. As analytical chemists, we strive to understand the composition of complex mixtures, especially new creations from sources such as plastic waste pyrolysis.

Benefits of pyrolysis

When done effectively, plastic pyrolysis offers several benefits.

By expanding recycling beyond just plastic bottles and milk jugs, pyrolysis could reduce the amount of plastic waste pollution that ends up in landfills and oceans.

Additionally, converting plastic waste into usable products could help lower the production demand for new plastics from petroleum hydrocarbons. The byproducts could get used in recycled plastics.

Some researchers are also testing pyrolysis oils to see whether they can use them instead of gasoline to fuel vehicles. The gases produced during pyrolysis can even generate energy that fuels the pyrolysis reactor, making the process more self-sustaining and reducing the need for external energy sources.

Currently, about 15% to 20% of the pyrolysis products are recycled into new propylene and ethylene, while most – about 80% to 85% – becomes diesel fuel, hydrogen, methane and other chemicals.

While plastic pyrolysis holds some promise, it also faces challenges. The cost of setting up and operating pyrolysis plants is high. How profitable the process is depends on the availability of suitable plastic waste, the market demand for the oils and gases produced, and the costs of energy and staff necessary to operate the reactor.

Another issue is quality control. Most plastic types can undergo pyrolysis, but different plastics create oils with different chemical makeups. Scientists will need to understand the composition of these oils before industry can determine which plastic types to focus on and how each oil could create new materials.