- Continuous Screw Pyrolysis Plant

- Continuous Twin-Screw Pyrolysis Plant

- Continuous Rotary Kiln Pyrolysis Plant

- Semi-Continuous Rotary Kiln Pyrolysis Plant

- Batch Rotary Kiln Pyrolysis Plant

- Recovered Carbon Black Refining Plant

- Pyrolysis Oil Refining Plant

- MSW to Energy Plant

- Industrial Solid Waste to Energy Plant

- Waste Gas to Energy Plant

01

Pyrolysis Oil Refining Plant

Advantages

Short range molecular distillation adopts atomized flash distillation technology, which has incomparable advantages over other separation technologies;

1. Low working temperature (far below the boiling point), high vacuum (no-load ≤ 5pa), short heating time (in seconds) and high separation efficiency. It is especially suitable for the separation of substances with high boiling point, heat sensitivity and easy oxidation.

2. It can effectively remove low molecular substances (deodorization of tire oil and plastic oil), heavy molecular substances (decolorization) and impurities in the mixture.

3. The oil temperature is between 100- 120 ℃, the vacuum degree is 200-300pa, and the light gasoline and diesel components are pulled out.

4. The oil temperature is 150- 190 ℃, the vacuum is 20-50pa, and the diesel component is pulled out.

5. The residual oil extracted from processing is sold as a by-product of industrial fuel oil.

6. The rectification equipment and auxiliary facilities of tire oil and plastic oil are sealed, the tail gas is collected and incinerated at high temperature (into the heating furnace for combustion support) for disposal, and there is no "waste gas" discharged during production.

7. This process technology does not require pretreatment of raw crude oil; Sulfuric acid and clay are not used, so there is no "waste residue" discharge.

TECHNICAL DATE

Oil yield as follow (calculated by oil net weight without water):

1. light industry fuel oil :85-90%.

2. Oil quality stander: Non standard diesel

3. High automation and uncomplicated operation, it can operate with only 1 or 2 persons. The time for learning is about 3 to 4 days.

Test Value:

Models of Waste oil distillation

| 1 | Feeding system | 8 | Cooling Tower |

| 2 | Pyrolysis Reactor | 9 | Extra Gas burning Room |

| 3 | Reactor Basement and Bruning Room | 10 | Sync Gas Purifying System |

| 4 | Gas Separator | 11 | Water Seal |

| 5 | Condensers | 12 | Smoke Clean System |

| 6 | Oil Tanks | 13 | Chimney |

| 7 | Carbon Black Discharging System | 14 | Control Cabinet |

Test Value:

| NO | Test Item | Test method | Test value | Standard value |

| 1 | Viscosity(15c) | ASTM D1298 | 0.84kg/L | .....kg/L |

| 2 | Viscosity lndex(40c) | ASTM D445 | 3.36cst | 1.6-5.8cst |

| 3 | PourPoint | ASTM D97 | - 19℃ | ≥0℃ |

| 4 | Flash Point(open) | ASTM D93 | 60℃ | ≥55 |

| 5 | Water Content | ASTM D95 | Trace%vol | ≤Trace %vol |

| 6 | Sulfur Content | ASTM D1226 | 0.15%Wt | 0.2%Wt |

| 7 | Color of distillation | Yellow and transparent | ||

Models of Waste oil distillation

| Models designation | Unit | MC-O-5 | MC-O- 15 | MC-O-C20 | MC-O-30 | MC-O-50 | MC-O- 100 | |

| Handling Capacity | Tons /Day | 5 | 15 | 20 | 30 | 50 | 100 | |

| Working Pressure | Mpa | ≤0.5 | ||||||

| Working vacuum | pa | -5~ -20 | ||||||

| Temperatur e | ℃ | ≤350 | ||||||

| Workin Noise | dB ( A) | ≤85 | ||||||

| Power voltage | V | 380-480V/50-60Hz | ||||||

| Total Power | KW | 80 | 120 | 12 | 140 | 180 | 210 | |

| Cooling Water | M³ | 35 | 40 | 5 | 60 | 80 | 160 | |

| Weight | T | 16 | 19 | 22 | 26 | 46 | 56 | |

| Size | L | m | 15 | 17 | 17 | 25 | 35 | 45 |

| W | m | 4 | 6.5 | 10 | 12 | 16 | 20 | |

| H | m | 6 | 6 | 6 | 6 | 6.5 | 8 | |

| Note | 1.we can provide 150-300T/D machine according to customer project requirement;2.we can customize the heating way, such as diesel oil and natural gas. | |||||||

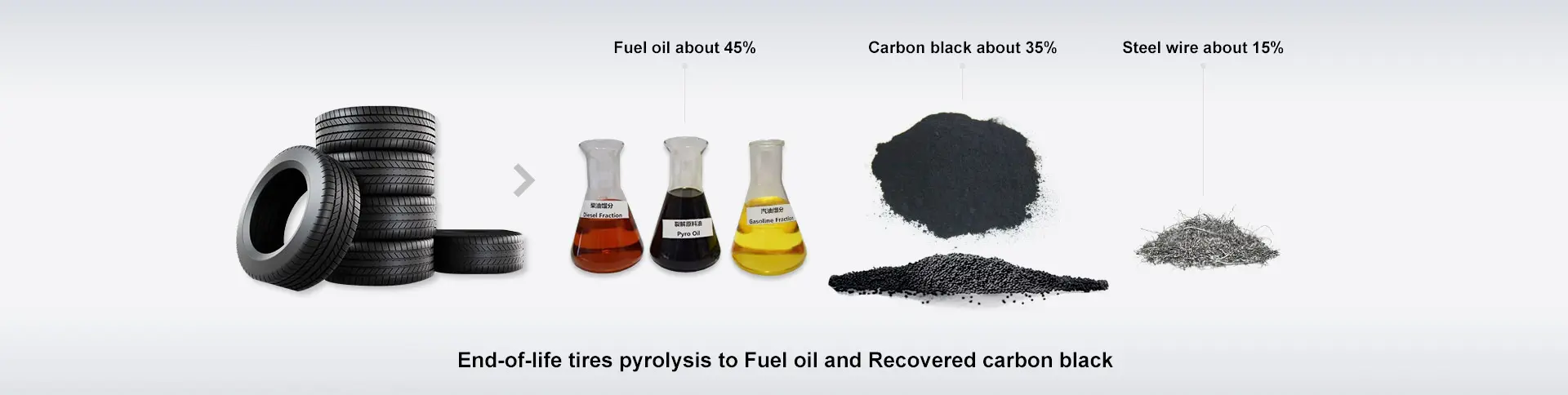

Fuel Oil Application

When the whole process is over, we can get end-products that have a wide range of applications. For example, the pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc. or used for generators to get electricity. The carbon black can be used for making construction bricks with clay, or used as fuel. The steel wire can be sold directly or recycled to produce new steel products.

CUSTOMER CASE VIDEO

Contact Us