- Continuous Screw Pyrolysis Plant

- Continuous Twin-Screw Pyrolysis Plant

- Continuous Rotary Kiln Pyrolysis Plant

- Semi-Continuous Rotary Kiln Pyrolysis Plant

- Batch Rotary Kiln Pyrolysis Plant

- Recovered Carbon Black Refining Plant

- Pyrolysis Oil Refining Plant

- MSW to Energy Plant

- Industrial Solid Waste to Energy Plant

- Waste Gas to Energy Plant

01

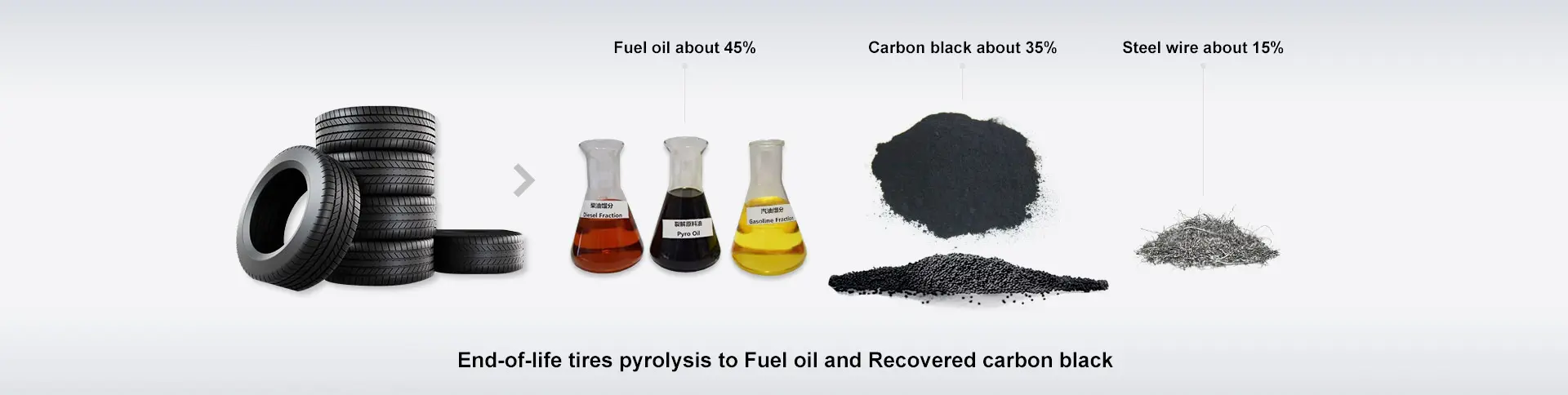

Recovered Carbon Black Refining Plant

Features

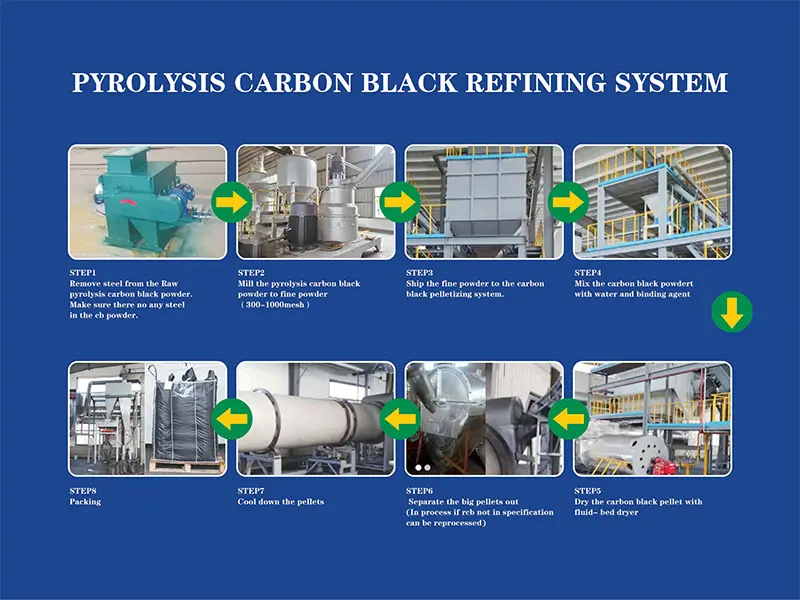

1. Low energy consumption: The comminution combines centrifugal comminution,

impact comminution and extrusion comminution, saving 40-50% energy than other types of mechanical comminutors.

2. High fineness: equipped with self splitting classification system, product fineness ≥

1000 mesh. (Raymond fineness can only be below 300 mesh)

3. Large feeding range: the feeding particle size is ≤ 10mm, and the material only needs to pass through the primary coarse breaking equipment.

4. Low wear: the comminuted vulnerable parts are made of composite wear-resistant new materials with long service life.

5. No pollution: negative pressure production, no dust pollution, excellent environment.

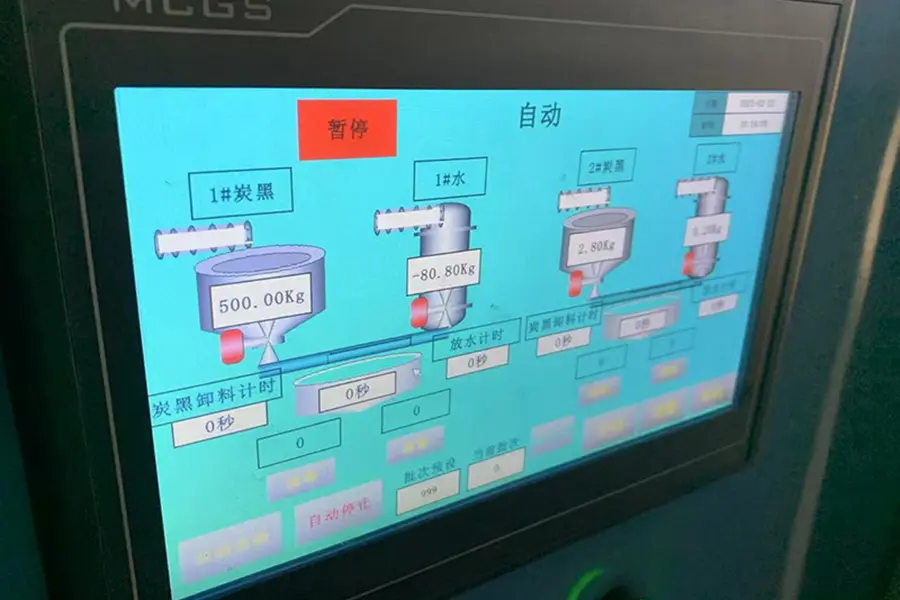

6. High degree of automation, strong stability and simple operation.

7. No adhesive: the granulation process uses physical principles to make dust carbon black and water strongly mix and bond, without adding any chemical adhesive.

8. No dust pollution: the machine is wet, negative pressure and continuous granulation. No dust escapes during granulation.

9. Large granulation strength: This machine forcibly agglomerates the powder into spherical particles through the high-speed rotation of the rotating part with stirring teeth. Compared with natural agglomerating granulation devices (such as rotary disc granulator and rotary drum granulator), it has a concentrated particle size distribution, and the particle strength is greater than that of natural agglomerating particles.

10. High granulation rate: granulation rate ≥ 99%.

11. The finished product is beautiful in appearance: the particles are spherical in shape, uniform in size, sphericity ≥ 0.8, and the particle size is generally 0.7-1.5mm.

12. Easy to control: the size of the particle diameter can be adjusted appropriately by the moisture content of the material and the rotation speed of the main shaft.

13. High working efficiency: the whole machine has a compact structure, stable and

reliable operation, large production capacity, and can granulate 1-2 tons per hour (the output is affected by volatile matter)

14. Save manpower: high degree of mechanization, labor saving, the whole production process only needs 3-4 people.

15. Strong mechanical stability: long-term 24-hour production without shutdown.

16. Less floor area: the drying adopts drum drying and three-dimensional installation,

which has compact structure, less floor area, reliable work, low energy consumption and high thermal efficiency.

17. The drying effect of materials is good, and the moisture content of finished products is ≤ 1%.

TECHNICAL DATE

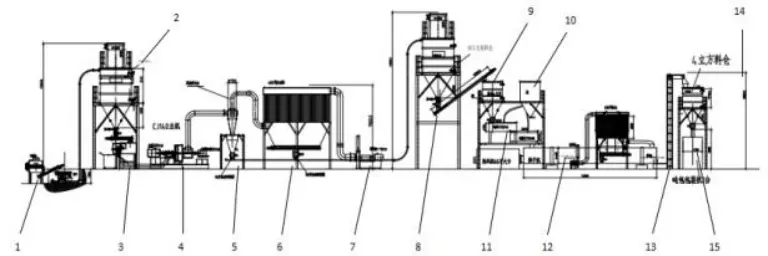

| 1 | Feeder | 6 | Dust-collector | 11 | Granulator |

| 2 | Raw material silo | 7 | Draft fan | 12 | Dryer |

| 3 | Iron separator | 8 | Storage bin | 13 | Bucket elevator |

| 4 | Mill | 9 | Feeding bin of carbon black | 14 | Finished product silo |

| 5 | Cyclone collector | 10 | Feeding bin of water | 15 | Packing |

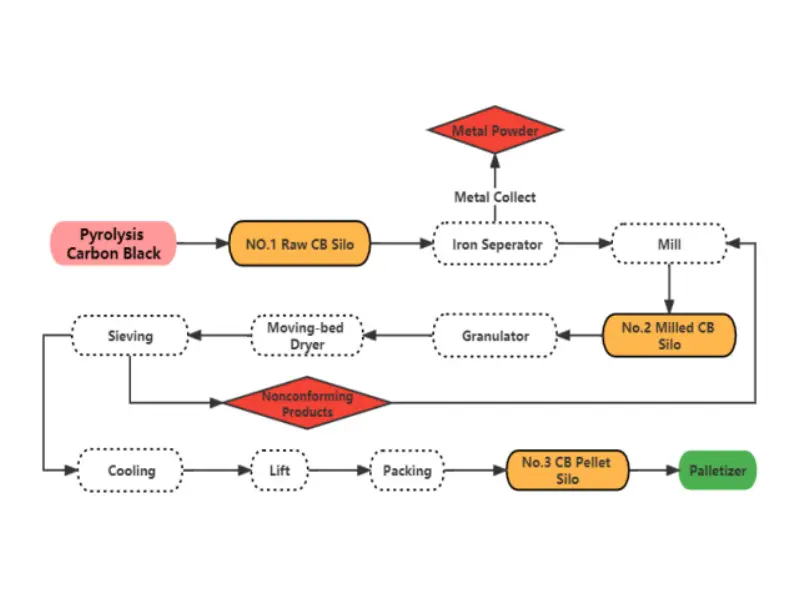

Flow Chart

APPLICATION

The finished carbon black has a balling rate of more than 95%, high finish, uniform particles, a fineness of more than 350 mesh, a particle size of 0.7-1.5 mm, and a heating reduction of less than 2%. It has a similar strengthening effect (tensile strength) to N550, a similar modulus value (constant tensile stress) to n772, a similar tear strength to N330, and a similar reinforcing effect to n660. In the rubber formula, it not only has a good filling and reinforcing effect, but also can improve the dispersion uniformity of carbon black in the rubber mixture and improve the processing performance of rubber semi-finished products. It has been applied to the inner ply cord rubber, outer ply rubber, sidewall rubber, inner liner rubber and inner tire rubber in nylon bias tire. Without adjusting other ingredients in the above original formula, 20- 30 parts by mass replace conventional carbon black such as N550 / 772, It does not affect the quality of the finished tire. In addition, pyrolytic carbon black is also widely used in rubber products such as cables, tapes, seals, rubber rollers, etc.

CUSTOMER CASE VIDEO

Contact Us