- Continuous Screw Pyrolysis Plant

- Continuous Twin-Screw Pyrolysis Plant

- Continuous Rotary Kiln Pyrolysis Plant

- Semi-Continuous Rotary Kiln Pyrolysis Plant

- Batch Rotary Kiln Pyrolysis Plant

- Recovered Carbon Black Refining Plant

- Pyrolysis Oil Refining Plant

- MSW to Energy Plant

- Industrial Solid Waste to Energy Plant

- Waste Gas to Energy Plant

01

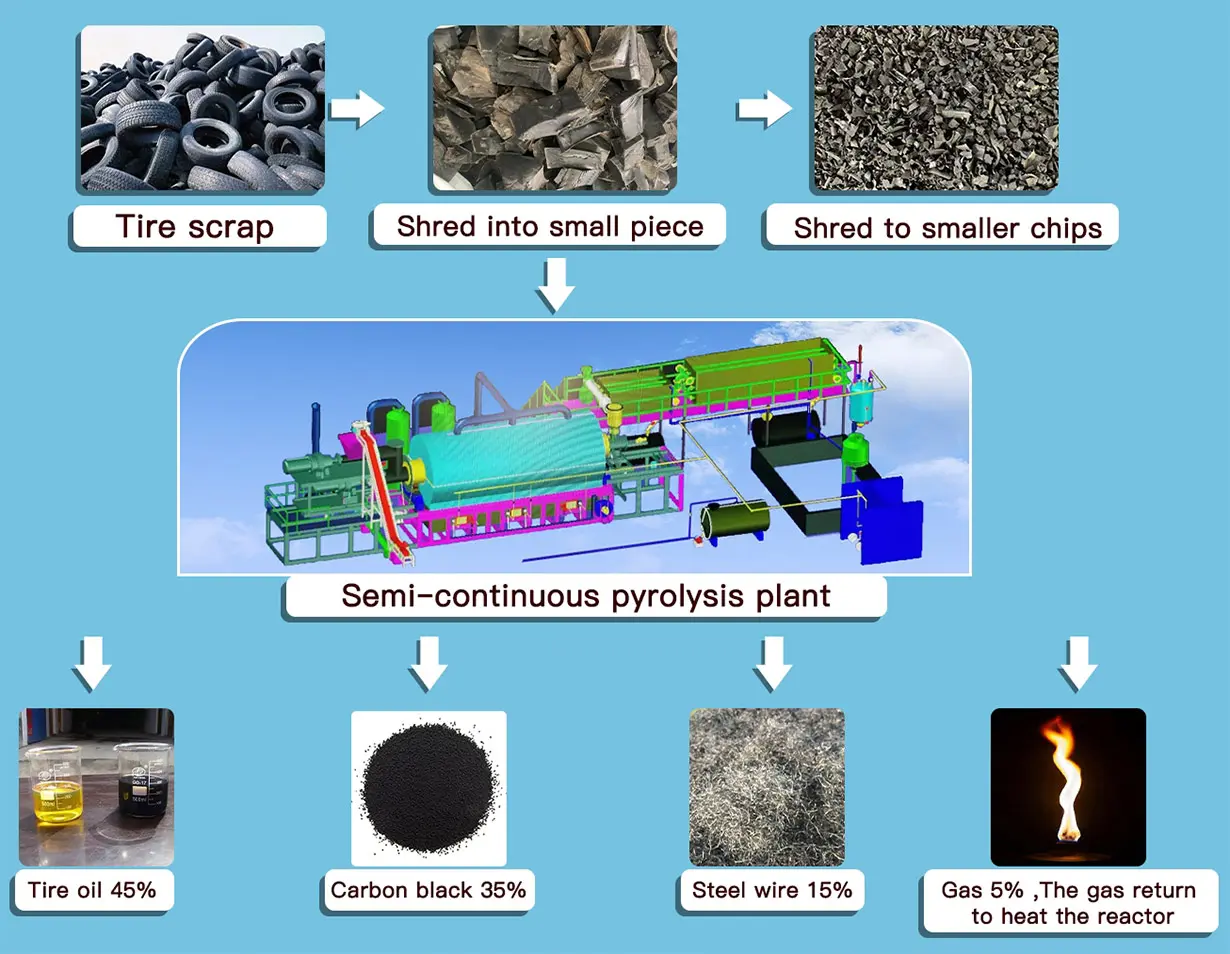

Semi-Continuous Rotary Kiln Pyrolysis Plant

Features

Semi-continuous rotary kiln pyrolysis plant also belongs to drum pyrolysis reactor. It is our second generation technology. It is much cleaner compared with batch model pyrolysis plant because it adapt auto feeding and discharging system. It also save the waiting time to cool down the reactor. No need wait about 8-10 hours like batch model, can load the raw material soon after last batch production.

| 1 | Feeding system | 8 | Cooling Tower |

| 2 | Pyrolysis Reactor | 9 | Extra Gas burning Room |

| 3 | Reactor Basement and Bruning Room | 10 | Sync Gas Purifying System |

| 4 | Gas Separator | 11 | Water Seal |

| 5 | Condensers | 12 | Smoke Clean System |

| 6 | Oil Tanks | 13 | Chimney |

| 7 | Carbon Black Discharging System | 14 | Control Cabinet |

WORKING PROCESS

1. Feeding

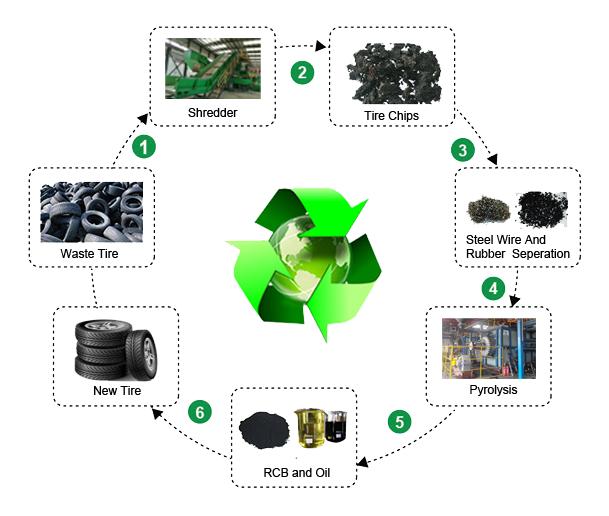

Shred the waste tire into tire granulate and then send them into the pyrolysis reactor through the auto-feeder.

2. Pyrolysis

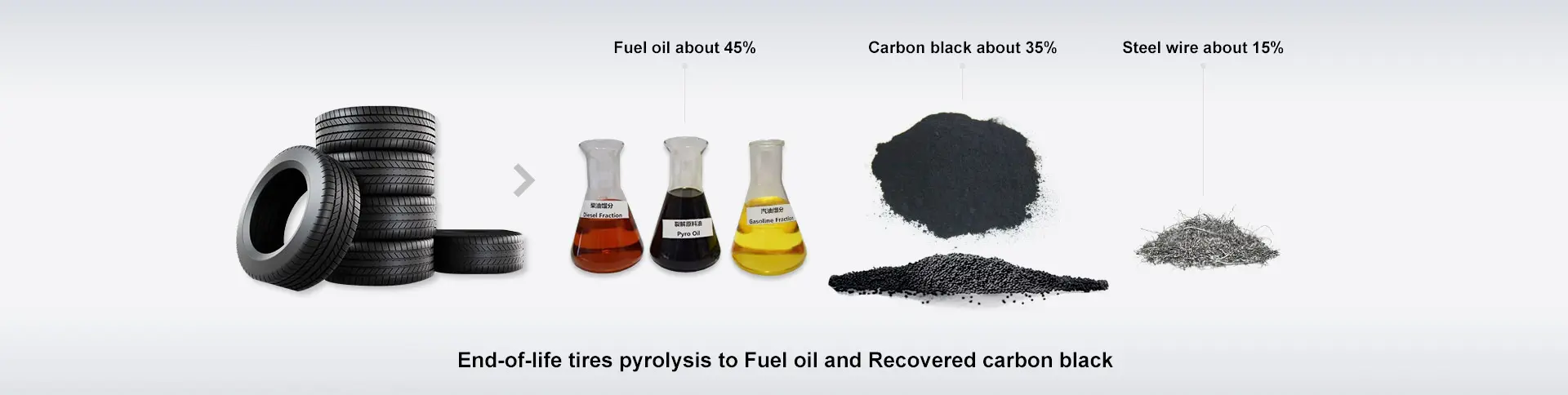

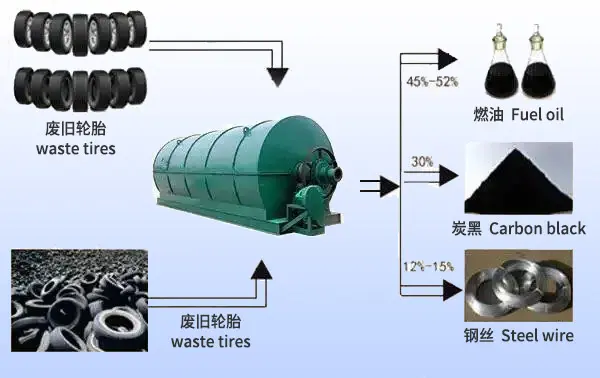

After the pyrolysis reactor is continuously heated to a certain temperature, the waste raw materials will be pyrolyzed to produce fuel oil carbon black and syn-gas.

3. Condensation

The oil gas first enters the buffer tank to buffer the flow rate and settle impurities, and then enters the condensation system to fully condense into oil.

4. Exhaust Gas Purification

The non-condensable gas enters the exhaust gas purification system to remove harmful emissions such as H2S, and can be used to heat the pyrolysis reactor after purification,which is energy-saving and environmentally friendly.

5. Flue Gas Purification

The flue gas generated during the pyrolysis process is treated by the flue gas purification system-desulfurization dedust tower, and then discharged up to standard.

6. Carbon Black Slagging

The residual substance(carbon black)in the pyrolysis reactor, is discharged and collected through the carbon black transfer system.

7. Steel Wire Collection

If your raw material is waste tires, when the temperature of the reactor drops below 50°C, use a wire drawing machine to pull out the steel wire in the reactor.

| Item | Raw Materials | Output |

| Tyres | Steel Tyres | 40%~45% |

| Nylon Tyres | ≈40% | |

| Tyres of Bikes etc. | ≈35% | |

| Plastics | HDPE | ≥70% |

| LDPE | 30%~50% | |

| PVC | 20%~30% | |

| ABS | ≈40% | |

| Paper Mixture | Rough Material | ≈15% |

| Washing Material | 23%~26% | |

| PE Material | ≈70% | |

| Cable Skin | PE Cable Skin | ≈85% |

| PVC Cable Skin | ≈25% | |

| Pure Rubber Cable Skin | ≈35% | |

| Telephone Line | ≈50% | |

| Life Garbage | Pure (Plastic bags) | ≈50% |

| Weaves & Handbags | ≈60% | |

| FIshing/safety Net | 45%~50% | |

| Instant noodles bags | ≈40% | |

| Wet Mixture | ≈15% | |

| Soles | Sports Shoes Soles | 27%~33% |

| Black Rubber Soles | ≈35% | |

| Gum-rubber Out-soles | ≈45% | |

| Others | Usual Rubber Tubes | ≈30% |

| Carpets | ≈35% | |

| Aluminum Foil | ≈30% | |

| Car Glass Bead | ≈50% | |

| PP)Beverage Bottle cap | ≈50% |

The Features of waste tyre pyrolysis plant

1. The complete set of waste tyre pyrolysis plant produces no smoke and smell with favorable effects of environmental protection.

2. The pressure release device operates through water circulation, which greatly improves the security of the system.

3. The release of pressure during the production dramatically increases the output within certain time and meanwhile improves the quality of oil.

4. The heating system adopts hot air heating technology, which improves the safety performance of production and heating efficiency. And the syn-gas produced in the waste tire pyrolysis process can be recycled to heat tyre pyrolysis reactor to save operation cost.

5. High efficiency fuel gas heating system. When the heated gas reaches 150 during pyrolysis process, a large amount of gas will be generated.

6. Whole tyre feed, no need to break for batch waste tyre pyrolysis plant for sale, which reduces cost.

TECHNICAL DATE

| Model | 2600-7800 |

| Reactor specification | Diameter 2600mm Length 7800mm Q245R 16MM Thickness |

| Working Power | 17KW |

| Working type | Semi-continuous |

| Price | |

| capacity | 12 tons tire powder per batch |

| Final products | Fuel oil & Carbon black |

| Shipment | 4*40 HQ containers |

| Delivery time | Within about 40 working days after receiving deposit |

| Model | 2600-7800 |

APPLICATION

When the whole process is over, we can get end-products that have a wide range of applications. For example, the pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc. or used for generators to get electricity. The carbon black can be used for making construction bricks with clay, or used as fuel. The steel wire can be sold directly or recycled to produce new steel products.

CUSTOMER CASE VIDEO

Contact Us