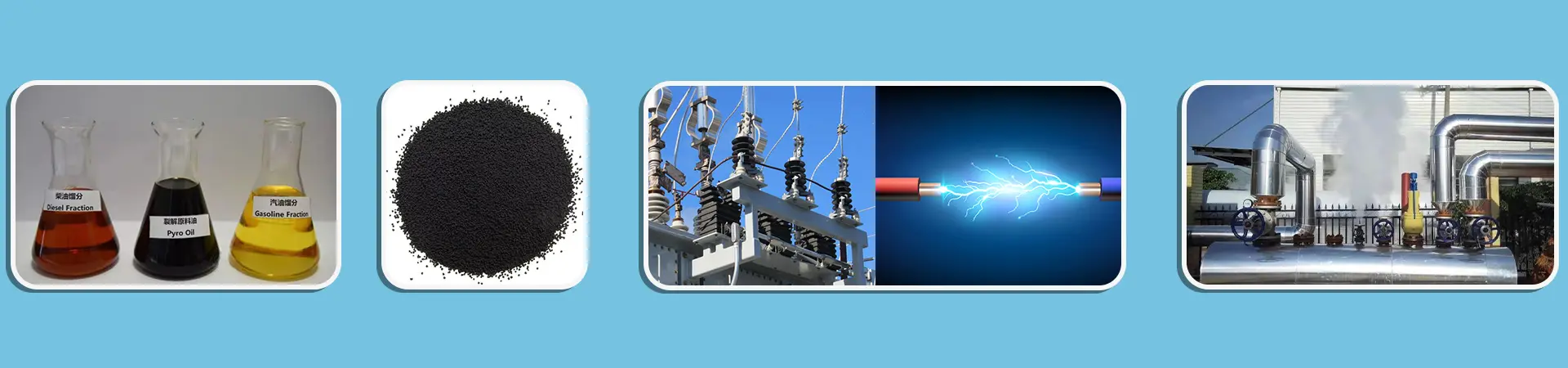

Solution of pyrolysis oil refining

This machine widely used in recycle tyre/tire oil into diesel, plastic oil into diesel and other pyrolysis oils into diesel. The waste oil distillation plant adopts high vacuum distillation process, it can convert waste oil into diesel, low cost, 85-95% high recovery rate, environmental and energy saving. The output diesel can be used as diesel fuel(not the standard diesel), it can be used in factories or big vehicles.

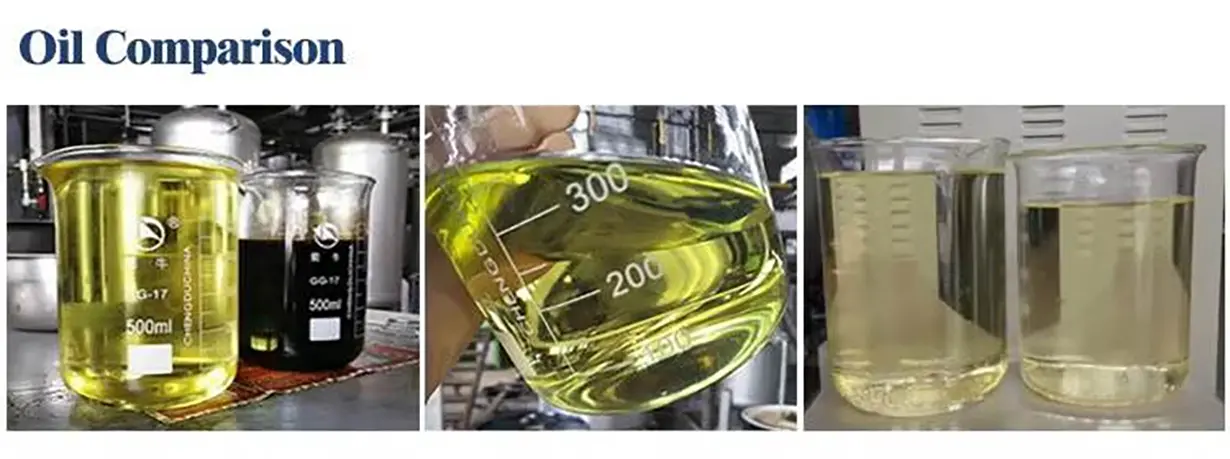

The decolorization of tire ol refers to the process of changing it from its original black or dark color to colorless or light color. The followingare several common tire oil decolorization processes:

Active soil decolorization method: Active soilis a substance with strong adsorption performance, which can adsorb impurities and pigmentsin tire ol, so as to achieve the purpose of decolorization. in the process, the active sol is usualy mixed with tire ol, and afer the active sollhas adsorbed the pigment, the active soll and impurities are separated by filtration or centrifugal separation to obtain the decolorized tireoil.Acid-base refining method: The process is mainly decolorized by pickling and alkali refining. First, the tire ol is added to the acid foroickling, which can remove impurities and pigments in the tire oll. Then, the pickling tire ol is alkali refined, and the acidic substancesremaining in the pickling are neutralized by adding an appropriate amount of alkal, and the pigments and impurities are further removed.

Oxidative decolorization method: Oxidative decolorization method uses oxidants to decompose the pigments in tire oll, so as to achieve thepurpose of decolorization. Commonly used oxidants include hydrogen peroxide, potassium permanganate, etc. in the process, the oxidizer isadded to the tire ol, and after the appropriate temperature and time, the pigment oxidation decomposiion reaction occurs, and finally thedecolorized tire oil is obtained.