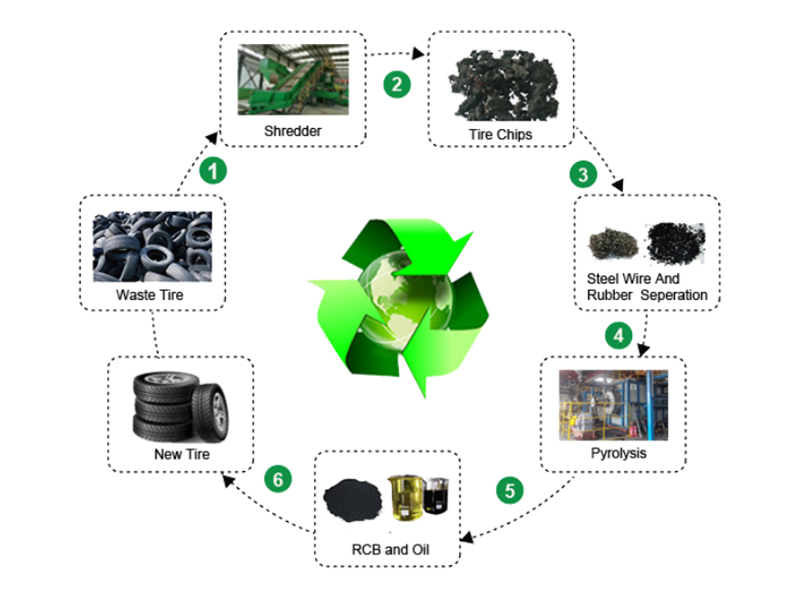

Solution of waste tires shredding

The Rubber Crumbs, Steel and Fiber can be separated automatically

The tire pre-shredding machine can be equipped with bolted cutting tools, which help reduce operational costs and simplify maintenance throughout the recycling line.

A two-stage rasper system efficiently separates steel from rubber, enabling high-quality separation and the production of clean wire.

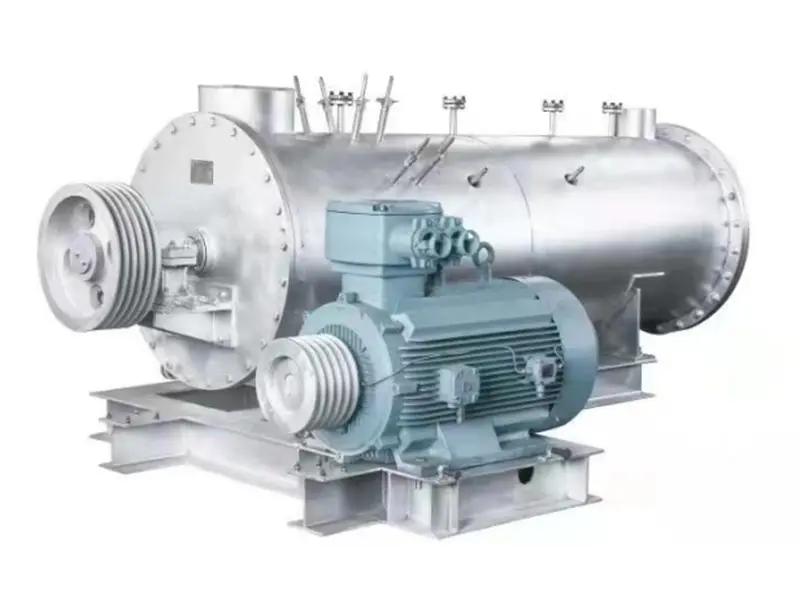

The fine granulation system features a specially designed rotor tailored for tire rubber size reduction. It delivers maximum throughput while minimizing the generation of fines. The system is also optimized for low operational and wear costs.

Textile and dust are extracted at multiple points within the recycling process, ensuring a cleaner working environment.

A centralized Reverse Jet Filtration System captures dust from the entire system, enhancing air quality and maintaining system efficiency.

An optional Milling System can be installed at the final stage of the tire recycling line. Its size and configuration are customized based on specific production requirements, including desired output size and throughput.

Advanced sound attenuation enclosures are available to reduce system noise levels to below 85 dBA, improving workplace safety and comfort.

Water spray and misting systems are integrated at key processing points to control operating temperatures and mitigate fire risk.

System automation ensures coordinated operation among components, maximizes throughput, and provides protection against contaminants or interfering materials.

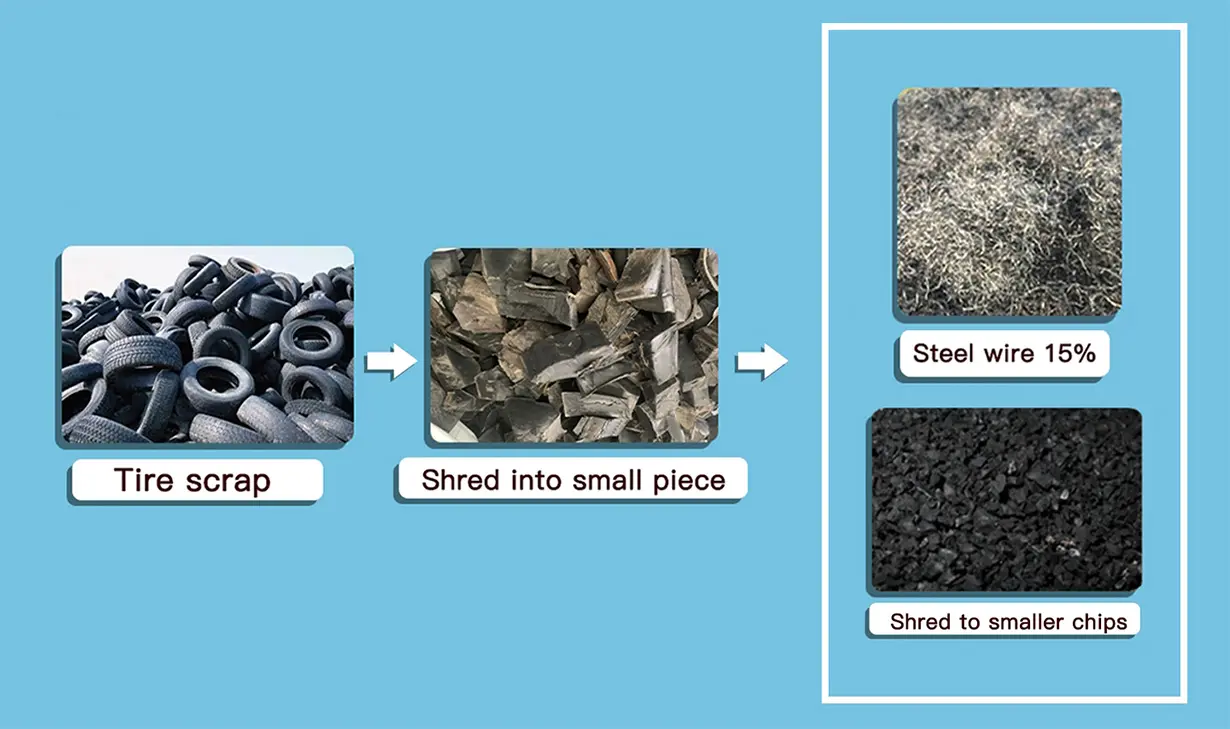

Capacity :200-10000 kg/h

Scope of Application: Diameter of the tire ,400-3000mm , including car tire/ passage tire/truck tire/OTR tire.

Output Size :5-100 mesh, Can be custom-made

Characteristic:

● Complete separation:The Rubber Crumbs、Steel and Fibre can be separated automatically.

● Control system:Adopt PLC control system, it is simple and easy to control and maintain. For example, it is only need 4-6 persons to operate a Tire recycling (beads) production line with 3000kg/h capacity.

● Low energy consumption:The installed power of Tire recycling production (beads) line with capacity 3,000kg/h is about 550kw.

Characteristic of blade: Long life cycle, High utilization, Multiple maintenance.

Equipment required area: About 400 square meter, 6 meter high

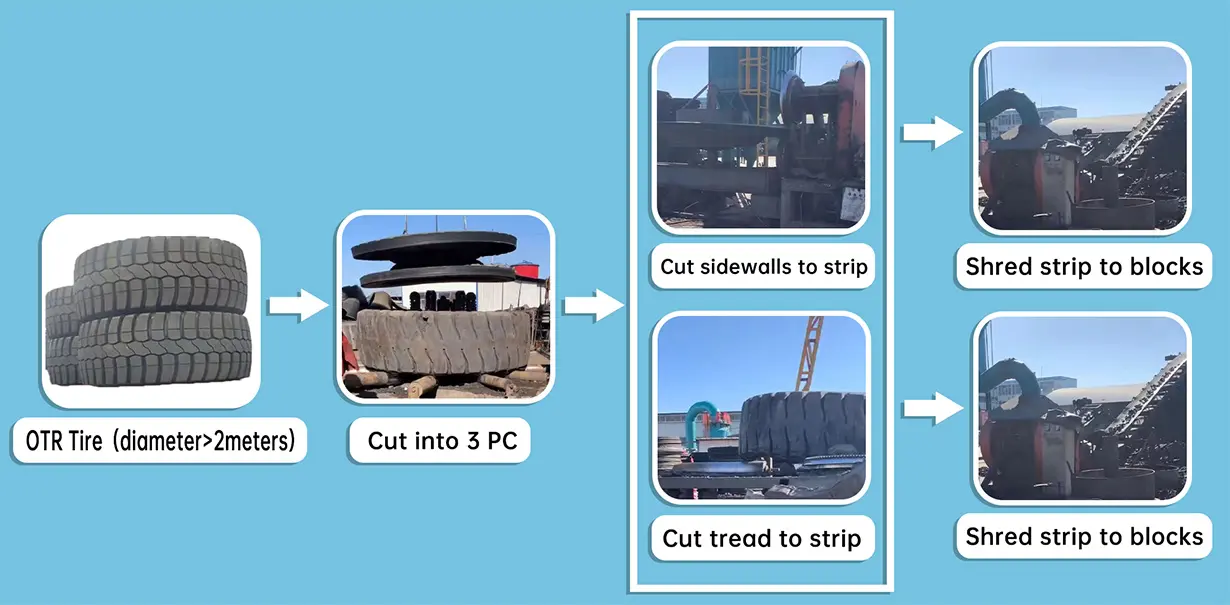

The recycling of giant tires(OTR tires) is a relatively difficult task because the large OTR tires are as big as a room and weigh a total of 4 about tons, which cannot be processed by a double shaft shredder. Every year, mines also produce a large number of waste OTR tires.

Here is our processing method:

First, the giant OTR tires are cut into three parts: one tread and two sidewalls.

Then they are made into rubber blocks.

There are 2 cutters. The Tread cutter and Side wall cutter.

Fist cut the tread and side wall into tire strip with tread cutter and side wall cutter. Then shred the tire strip to tire blocks. The size of tire block is about 12 cm long.

After obtaining the rubber blocks, the tire blocks goes into crusher. they are ground into rubber powder. During this process, the steel wire is also removed out.