Solutions of waste tire to fule oil and carbon black

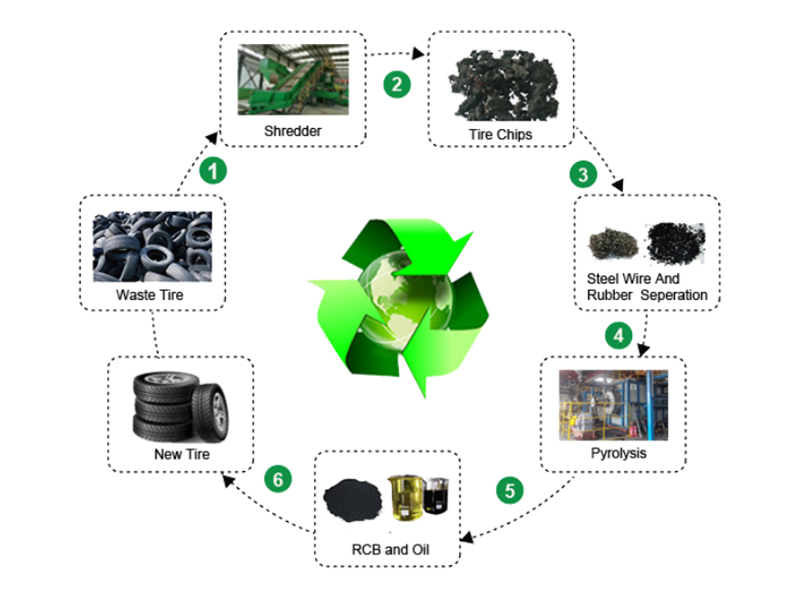

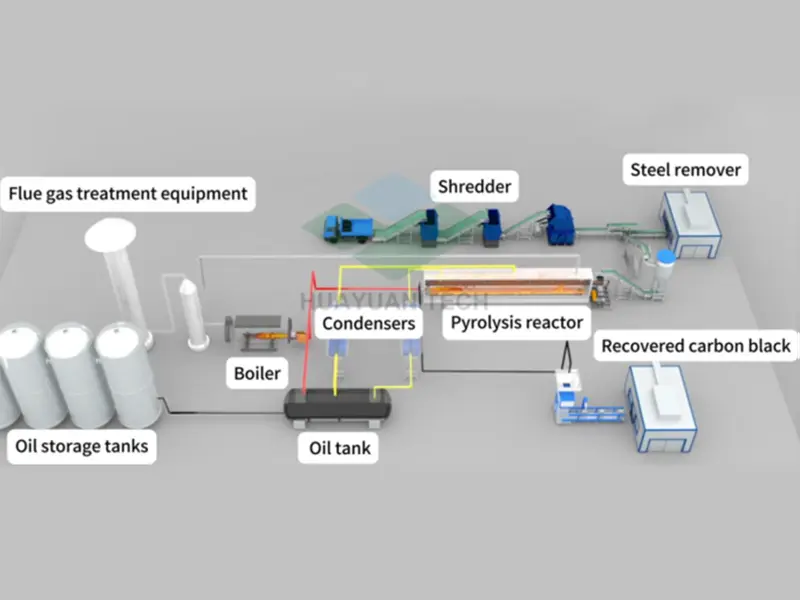

The tyre recycling to fuel oil pyrolysis plant is a kind of machinery that adopts advanced pyrolysis technology can convert waste tyre to fuel oil and carbon black.

Commercial-Scale Processing Capacity:

30-50 tonnes per day (TPD)

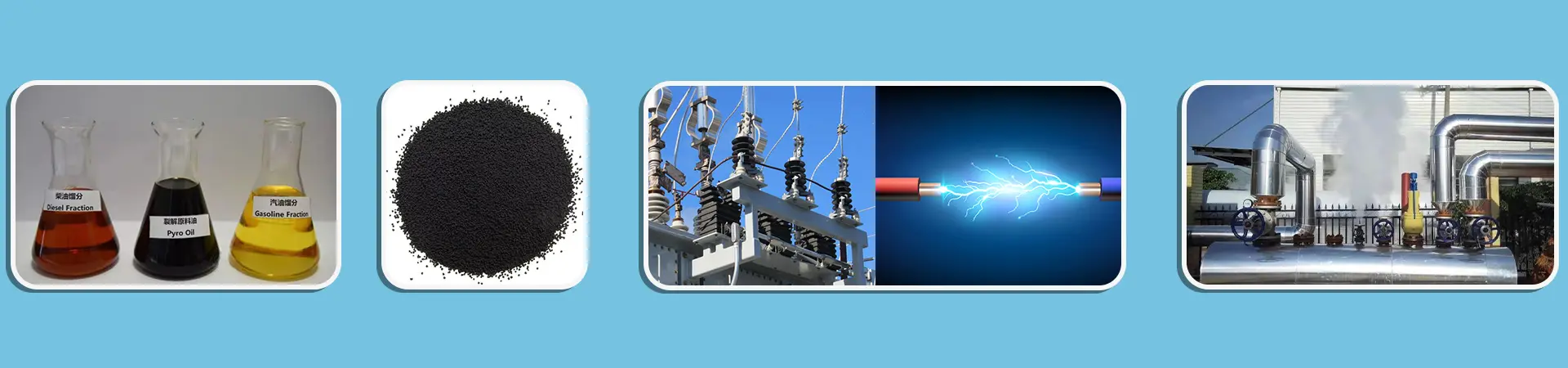

High-Value Recovered Products:

Recovered Carbon Black (rCB): a Sustainable replacement for virgin carbon black

Recovered Steel Wire & Fiber: a sustainable materials replacement for the construction industries

Biogenic Recovered Fuel Oil (rFO): Low-carbon fuel for transportation and industrial applications

Green Hydrogen Co-Production: Supporting Australia's clean energy transition

Advanced Carbon Upgrading Technology:

Transforms low-value tyre char into high-performance recovered carbon black

It can replace virgin carbon black by 10–100%, reducing reliance on fossil-derived carbon black

Enables closed-loop tyre-to-tyre recycling

Carbon Emission Offsets:

450 kg CO₂ reduction per metric tonne of recovered carbon black

Virgin carbon black production emits over 2.5 metric tonnes of CO₂ per tonne produced

Estimate to produce over 100,000 metric tonnes of CO₂ annually

HUAYUAN TECH’s Key Advantages:

• Proven Commercial-Scale Technology

Backed by decades of successful real-world performance in tyre pyrolysis and carbon upgrading.

• High-Quality Recovered Carbon Black (rCB)

Delivers consistent, high-performance material that meets ASTM standards.

• Sustainable Fuel Production

Generates biogenic pyrolysis oil suitable for low-carbon energy applications.

• End-to-End Circular Economy Integration

Enables tyre-to-tyre and tyre-to-fuel recycling models for a fully sustainable solution.

• Scalable & Modular Solutions

Engineered for global deployment with high-yield, flexible operations.