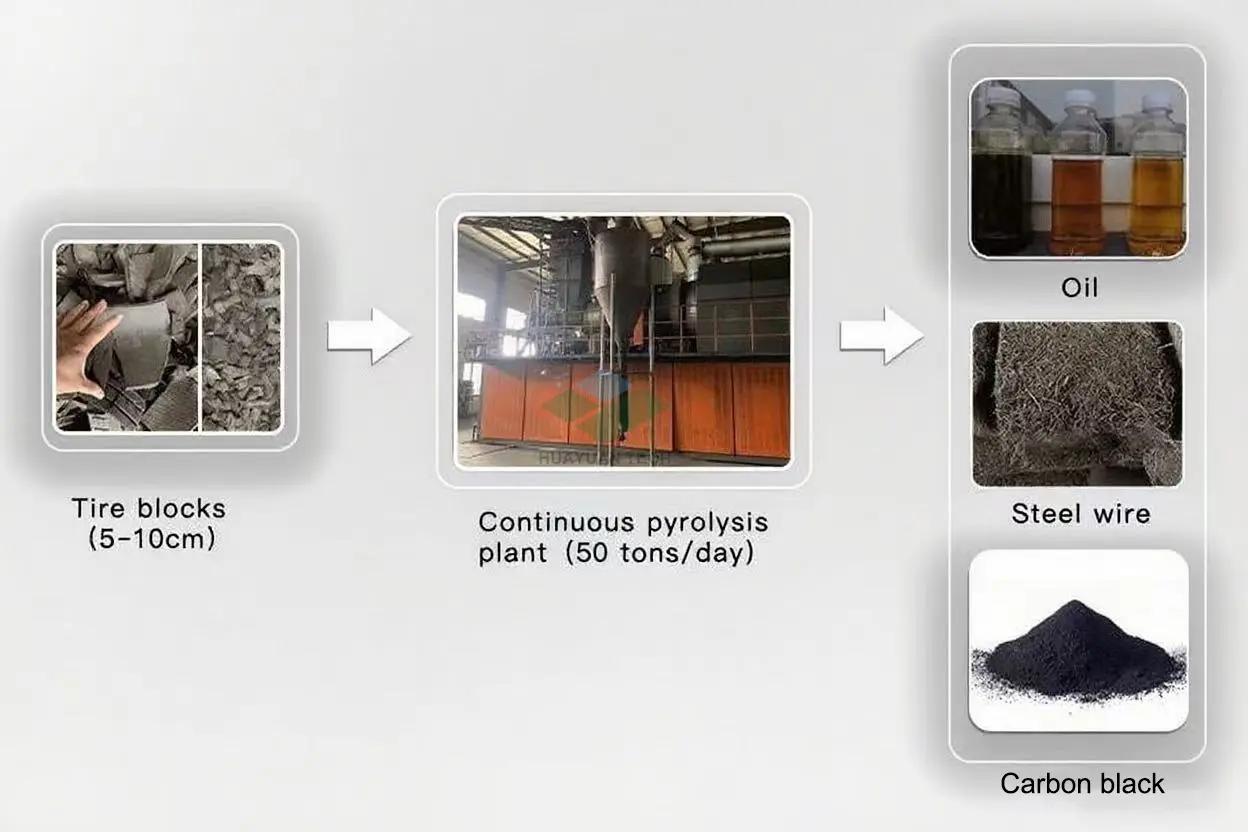

Continuous pyrolysis plant(5-10cm tire blocks as feedstock)

Our company has launched a revolutionary continuous tyre pyrolysis plant, processing 50 tons of 5-10 cm rubber blocks daily—eliminating the need for energy-intensive rubber powder production.

Unlike traditional methods, it feeds rubber blocks directly into the reactor, cutting electricity and labor costs. Operating continuously for 30-50 days, it produces high-quality fuel oil and carbon black, boosting profitability.

This sustainable innovation transforms tyre recycling with enhanced efficiency, lower costs, and strong returns, while our, a leading pyrolysis equipment manufacturer, delivers such cutting-edge waste-to-energy solutions globally.

Advantage:

1. Unique rotary seal design, with a long maintenance free operating cycle.

2. Special process design ensures that the carbon powder after pyrolysis meets industry requirements.

3. An effective defocusing layout greatly extends the cleaning cycle of the equipment

4. An independent safety control system effectively detects gas leaks and system oxygen levels.

5. An efficient feed control system that prevents combustible gases from escaping while feeding

6. Adopt various forms of combination processes for different materials to better ensure safe and efficient production.

7. Achieve leak free sealing of rubber block feeding and solve the problem of sealing of mixed discharge of rubber powder and steel wire.

8. Realize constant temperature adjustable heating.

9. Achieved long-term effective operation of the sealing system.