Continuous Waste Plastic Pyrolysis Plant(Double level reactor)

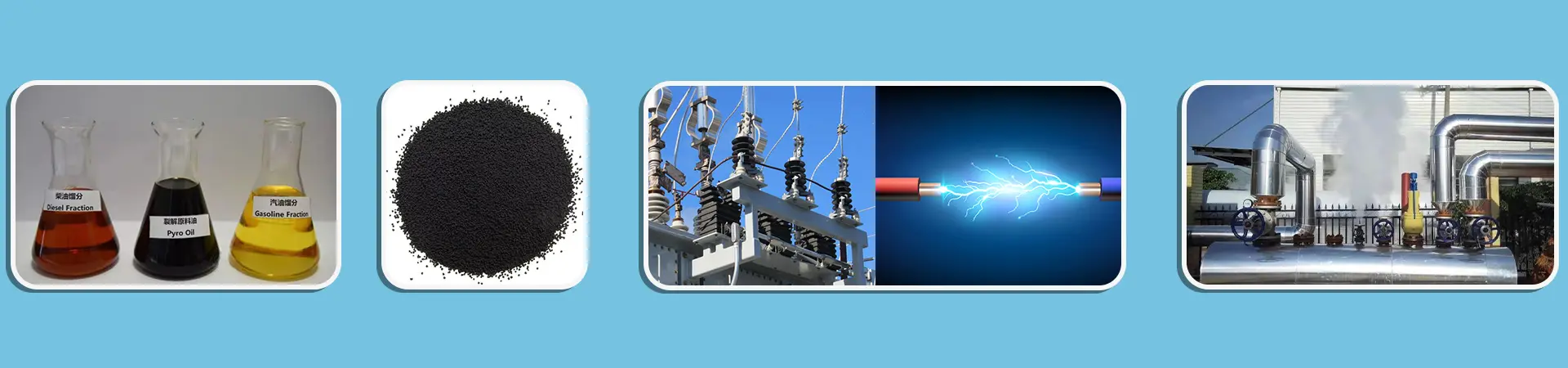

The industrial continuous production line for waste plastic pyrolysis is capable of processing a wide range of waste plastics, including PP, PE, PS, and both single-type and mixed plastics. During the pyrolysis process, these waste plastics are converted into high-value products such as pyrolysis oil and solid fuel. The pyrolysis oil can then be used as a raw material to produce new plastics through chemical recycling. This not only closes the loop but also maximizes resource recovery.

Fully Automated Operation

From the initial feeding stage to heating, temperature control, cracking, cooling, oil storage, carbon black collection, combustible gas collection for further utilization, and exhaust gas treatment, each process is seamlessly controlled through advanced PLC automation. Real-time monitoring of temperature, pressure, flow rate, and other operational parameters ensures optimal performance. Operators can conveniently manage the equipment’s operations from a central control room.

Remarkable Production Efficiency

While conventional batch pyrolysis equipment typically handles up to 10 to 15 tons per unit, our continuous equipment significantly boosts production capabilities, allowing for a daily processing capacity of up to 30 tons, with a maximum capacity of 50 tons. Moreover, thanks to advanced technological designs, our equipment features a more compact footprint, allowing for enhanced production efficiency compared to similar products available on the market.

Optimal Thermal Utilization

Our equipment employs a cutting-edge hot air heating system that ensures precise temperature control throughout the pyrolysis process. The reactor’s internal uniform temperature distribution reduces temperature differentials. Additionally, the reactor is designed with full coverage, eliminating heat loss from exposed areas. Consequently, our equipment achieves a significantly higher thermal utilization rate than other products in the market, leading to substantial energy savings and lower emissions.