Industrial continuous waste tire pyrolysis plant

This video mainly shows the on-site situation of the pyrolysis process of the fully continuous tire pyrolysis plant installed in China.It has been running continuously for over eight years, without coking, pollution, and running well.

This plant is the most advanced choice of pyrolysis plant. It adopts continuous produciton technology, providing daily capacity ranging from 30 tons to 50 tons per unit. The technical advantages include fully automated operation, top-notch safety features, impeccable cleanliness, high production efficiency, exceptional thermal utilization, extended lifespan, superior quality oil and carbon black production, and minimal maintenance requirements.

Due to the strict requirement for feeding raw materials, we need to make some pretreatment for waste tires before feeding waste tires into pyrolysis reactor to ensure the continuous feeding and discharging of the continuous waste tire pyrolysis plant.

First, the waste tires are broken into blocks of about 3.5 cm by crushing shredder machine; second, the tire fragments enter the grinder through the conveyor belt and are crushed and ground into rubber powder particles of about 17-18 mesh; third, the tire rubber powder will enter the sorting equipment to separate the steel wire and rubber powder, and finally a relatively pure rubber powder will be obtained. The rubber powder enters the silo for storage through the conveying equipment, which is the process flow of the entire production line of the waste tire pretreatment section.

After going through the tire pretreatment stage, the rubber powder can enter the next stage to complete the whole work process of the continuous waste tire pyrolysis plant. For more details about the whole recycling process, welcome to continue to pay attention to our website updates.

1. Feeding ——The raw material is automatically transported to the transition hopper via the feeding conveyor. This system can also achieve functions such as online weighing, conveying, and feeding sealing.

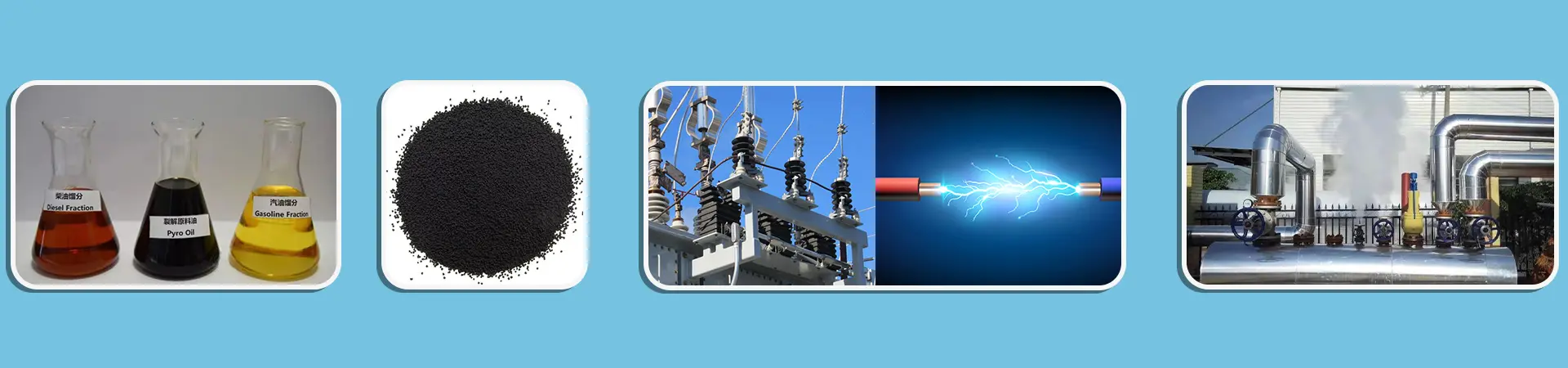

2. Pyrolysis——In the oxygen-free or oxygen-poor environment, the pyrolysis system function is to complete the pyrolysis reaction of organic waste or hazardous waste and convert the raw material into pyro oil, NCG and solid output under normal pressure, low pyrolysis temperature or catalyst action.

3. NCG scrubbing——While removing acid components in NCG, such as hydrogen sulfide, the pressure is also maintained within a reasonable range through the NCG scrubbing system. This process further supplies energy to downstream operations.

4. Circulating water cooling——The main function of this system is to cool the outputs from pyrolysis system and flue gas with water as cooling medium. The cooling water is circulated in the way of in-direct heat exchange, which does not contact any material directly, and there’s no waste water generated.

5. Oil separating and cooling——This system is to cool the gas phase output from pyrolysis reactor to the safe temperature and separate them according to the different boiling points.

6. Discharging——The main function of discharging system is to complete the discharge seal, cool and convey the solid output.

7. Flue gas purification——The main function of this system is to cool down and purify the flue gas. Through multi-stage purification and comprehensive treatment, the harmful substances in the flue gas can be removed, and the flue gas discharged into the atmosphere can meet the emission standards in various countries and regions.

8. Electrical control——Electrical control system adapts PLC/DCS control system to automatically control the control points. It also has the functions of date collection, calculation, record, printing record, safety alarming etc.