Pyrolysis Oil Refining Plant

Distillation is the process involving the conversion of a liquid into vapor that is subsequently condensed back to liquid form. In the application for recycling of waste engine oil and processing of pyrolysis oil, the feedstocks are heated to become gas state then the gas gets liquified by condensing and becomes liquid fuel. In the distillation process, the impurities are removed from the feedstocks.

Distilled in 2 fractions suitable for transportation Fuel markers Marine fuel & Gasoline blend components Avg weighted value USD500-690/mt Additional value and incentives by means of Advanced Renewable Energy Units.

Convert/Upgrade oil to petrochemical feedstock

Aliance with Plastic waste recycling Base Petrochemicals value Striving for "full circularity"

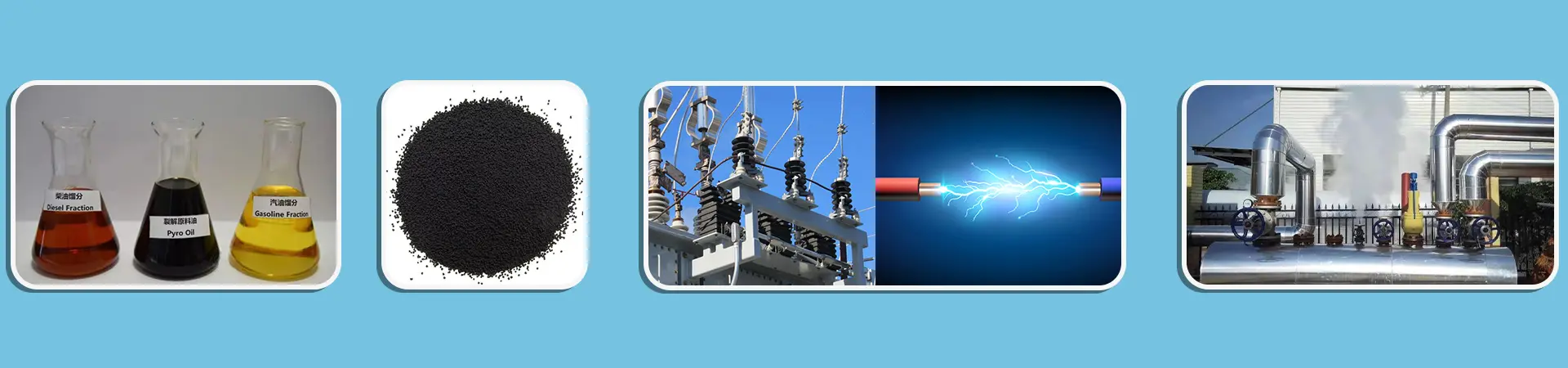

Pyrolysis oil are further purified into bright non-standard diesel or non-standard gasoline by pyrolysis oil distillation plant. This light fraction oil can be widely used in heavy-load low-speed diesel engines, ships, diesel generators, etc.