Recovered Carbon Black Refining Plant

RCB is an sustainable product that can be continuouslyrecycled by extracting carbon black from waste tires and using the extract as a rawmaterial for tires and mechanical rubber productsRCBis manufactured by refining, processing,and commercializing combustion residues(Char), gas, oil, and steel that aregenerated through pyrolysisafter shredding waste tires

Recovered carbon black refining

The recovered carbon black produced by the pyrolysis reaction must be processed through a series of processes to make it into recovered carbon black.

The environmental protection carbon black processing system includes magnetic separation, grinding, granulation and drying procedures, etc.

The processing process must undergo strict quality management procedures to ensure the stable quality of recovered carbon black.

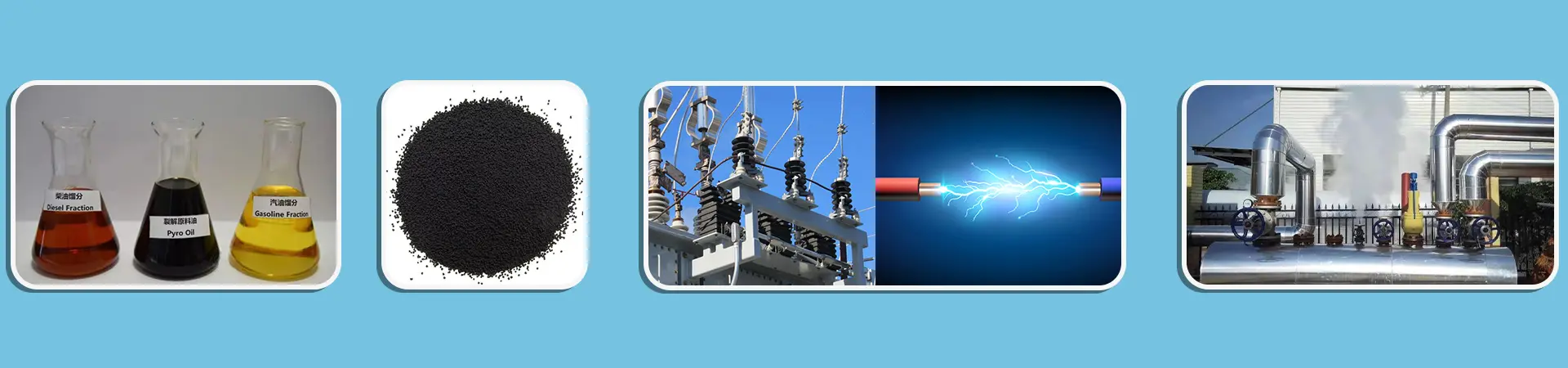

The uses of Recovered carbon blackas follows:

● Tires and Industrial Rubber Products: Carbon black is added to rubber as both a filler and as a strengthening or reinforcing agent. For various types of tires, it is used in inner liners, carcasses, sidewalls, and treads utilizing different types based on specific performance requirements. Carbon black is also used in many molded and extruded industrial rubber products, such as belts, hoses, gaskets, diaphragms, vibration isolation, bushings, air springs, chassis bumpers, and multiple types of pads, boots, wiper blades, conveyor wheels, and grommets.

● Plastics: Carbon blacks are now widely used for conductive packaging, films, fibers, moldings, pipes and semi-conductive cable compounds in products such as refuse sacks, industrial bags, photographic containers, agriculture mulch film, stretch wrap, and thermoplastic molding applications for automotive, electrical/electronics, household appliances and blow-molded containers.

● Electrostatic Discharge (ESD) Compounds: Carbon blacks are carefully designed to transform electrical characteristics from insulating to conductive in products such as electronics packaging, safety applications, and automotive parts.

● High Performance Coatings: Carbon blacks provide pigmentation, conductivity, and UV protection for several coating applications including automotive (primer basecoats and clearcoats), marine, aerospace, decorative, wood, and industrial coatings.

● Toners and Printing Inks: Carbon blacks enhance formulations and deliver broad flexibility in meeting specific color requirements.