- Continuous Screw Pyrolysis Plant

- Continuous Twin-Screw Pyrolysis Plant

- Continuous Rotary Kiln Pyrolysis Plant

- Semi-Continuous Rotary Kiln Pyrolysis Plant

- Batch Rotary Kiln Pyrolysis Plant

- Recovered Carbon Black Refining Plant

- Pyrolysis Oil Refining Plant

- MSW to Energy Plant

- Industrial Solid Waste to Energy Plant

- Waste Gas to Energy Plant

01

Waste to Energy Plant

ANIMATION VIDEO

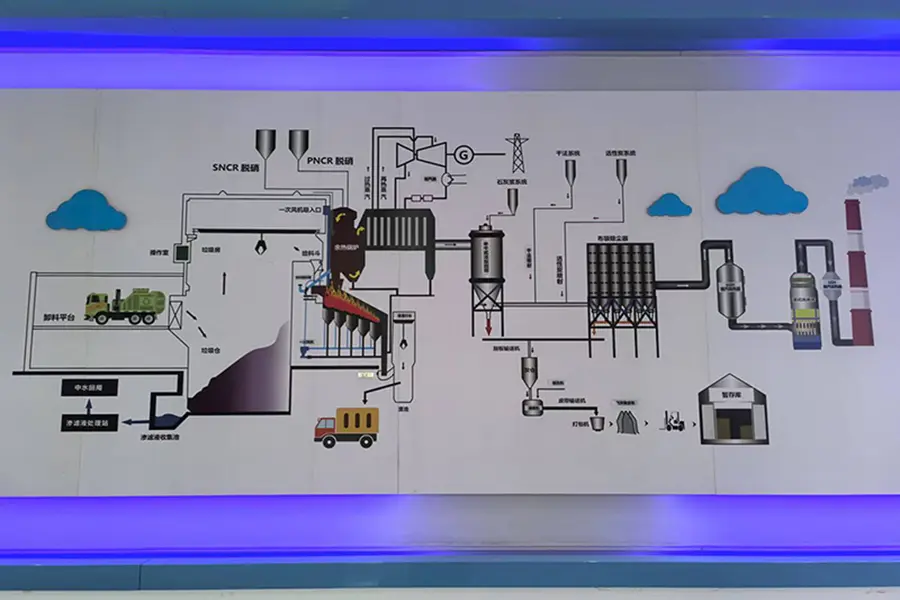

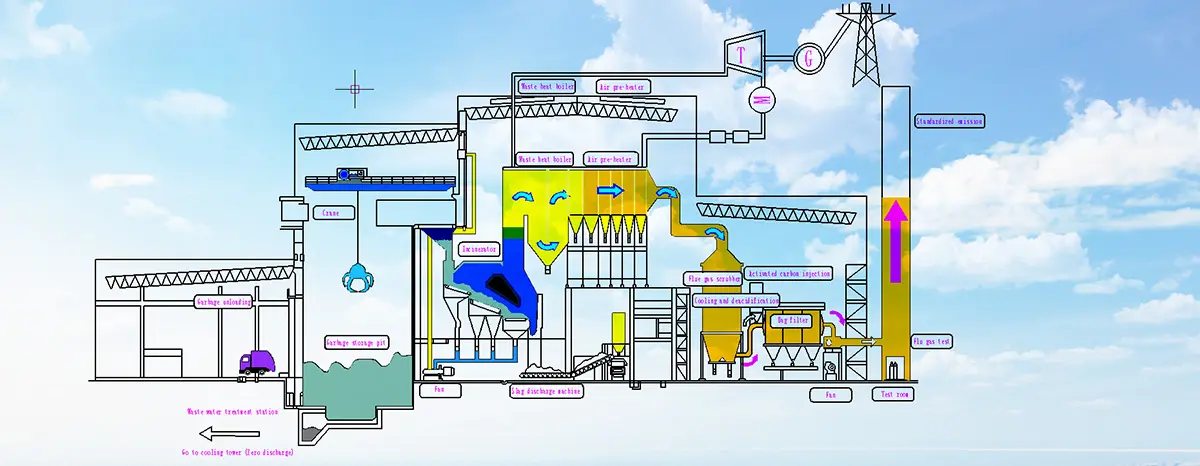

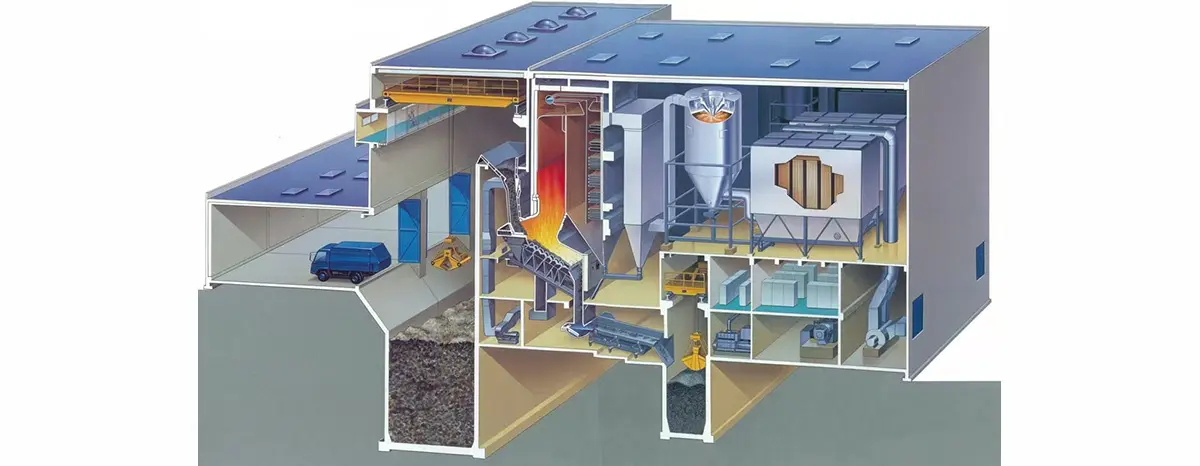

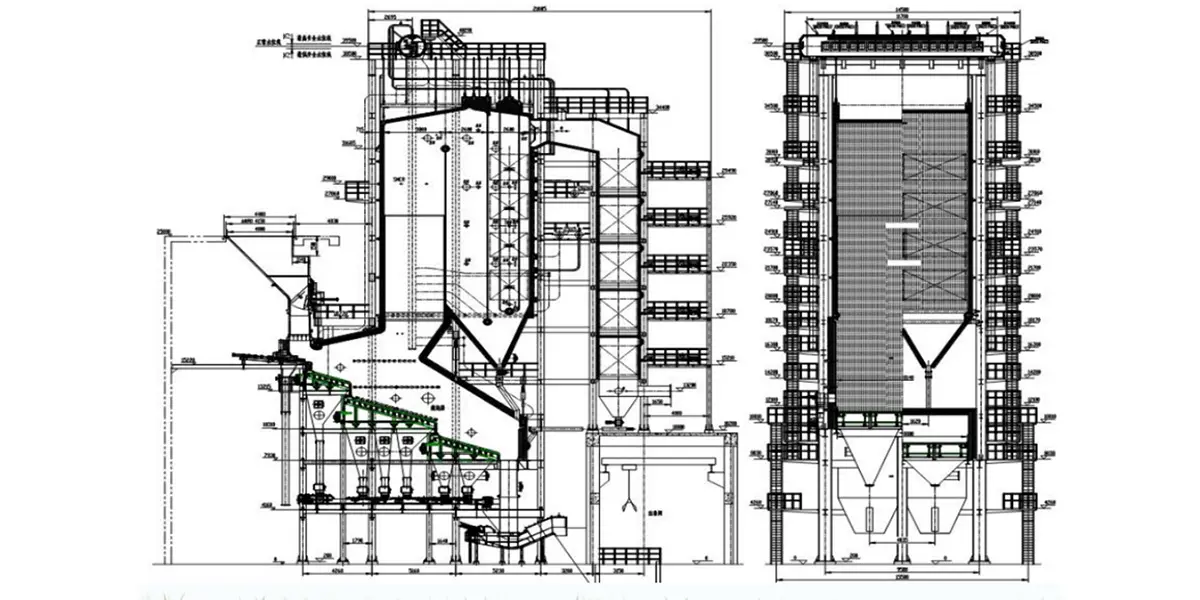

The waste to energy is composed of garbage incinerator, waste heat boiler, flue gas duct, denitrification system, deacidification tower system, dust collector system, boiler auxiliary machine, etc. The garbage is fed into the garbage feeding hopper by the grab, and is pushed into the incinerator by the pusher after passing through the bypass cracking device and the chute.The incinerator grate consists of three parts: the drying section, the burning section and the burning section,the burnt waste ash and dregs are discharged through a slag discharging machine. The high temperature flue gas produced by combustion is discharged from the chimney after it reaches the discharge standard through the waste heat boiler and the flue gas treatment system.

The waste heat boiler is a single-drum, natural circulation medium pressure boiler, which adopts suspension structure.The boiler is horizontal and consists of three vertical membrane water wall channels (i. e. Furnace I, combustion chamber II, convection shaft) .High-temperature superheater, middle-temperature superheater, low-temperature superheater and suspended tube superheater are arranged from bottom to top in convective shaft.A water-jet temperature reducer is arranged between the high and middle temperature superheater and the middle and low temperature superheater to adjust the steam temperature at the outlet of the superheater.

FEATURES

✤ Huayuan owns a complete set of core technologies of WTE boilers and waste incinerators, and have strong capacity in designing, manufacturing and supplying products with excellent quality.

✤ With the whole set of technologies and operation references of WTE boilers of large capacities, high parameters and/ or RH system, Huayuan is dedicated to create excess value for client.

✤ Furnaces of insulating, air cooling and water cooling types are developed to adapt different heating values of MSW(Municipal Solid Waste) and with large fuel flexibility.

✤ Front and rear arches are to be properly arranged on a case-by-case basis to reduce the loss of ignition and to increase the thermal efficiency.

✤ The heating surfaces are provided with efficient soot-blowing arrangement and proper layout to ensure the heat exchange efficiency.

✤ Mature and reliable anti-corrosion solutions for furnace, Superheater(high temperature corrosion) as well as economizer (low temperature corrosion).

✤ The structural layout is properly made so as to avoid coking on heat recovery area.

✤ Advanced manufacture technologies and complete quality assurance system to ensure the stability and reliability of the boiler operation.

CUSTOMER CASE VIDEO

TECHNICAL DATE

| Iain Performance Parameters of LC Series Solid Taste and Iunicipal Solid Taste Incineration Boiler | |||||

| Items | LC35-5-1.25 | LC40-5-1.25 | LC60-6-1.25 | LC60-8-1.25 | ALC120-12-1.25 |

| Rated output(t/h) | 5 | 5 | 6 | 8 | 12 |

| Rated Torking Pressure (Ipa) |

1.25 | 1.25 | 1.25 | 1.25 | 1.25 |

| Steam temperature (°C) |

Saturated(194) | Saturated(194) | Saturated(194) | Saturated(194) | Saturated(194) |

| Combustion mode | Chain layer combustion | Chain layer combustion | Chain layer combustion | Chain layer combustion | Chain layer combustion |

| Fuel type | Coa1,firewood | Coa1,firewood | Waste of paper material (humidity <20%,sand content <5%) | Maste of paper material (humidity <20%,sand content <5%) | Waste of paper material (humidity <20%,sand content <5%) |

| Grate area(m²) | 10 | 8.3 | 8.9 | 11.2 | 18 |

| Heated surface of boiler proper(m²) |

188.9 | 232.2 | 255 | 254.7 | 372.6 |

| Heating surface of boiler tail(m²) |

99.3 | 99.3 | 99.3 | 99.3 | 8497 |

| Iaximum size of transportation cargo (L××H)(mm) |

5740×2830×3550 | 6320×3230×3550 | 8750×3240×3550 | 7770×3400×3550 | 8200×3350×2930 |

| laximm weight of transportation cargo (t) |

23 | 28 | 34 | 34 | 60 |

| Daily treatment waste amount(t/d) |

~35 | 40 | 60 | 60 | 120 |

APPLICATION

The technology has been widely used in municipal solid waste treatment, waste incineration for power generation, waste incineration in paper industry, general solid Waste treatment, urban central heating and other fields.

Contact Us